Bamboo chopstick sorting machine solution

Bamboo chopstick sorting machine solution

Automatic, high-speed, stable, and precise sorting greatly enhances product quality.

Xinje's bamboo chopstick sorting machine solution, powered by AI deep learning and using standard industrial cameras, enables automatic, high-speed, and precise sorting of bamboo chopsticks. It offers high stability and efficiency, surpassing manual quality inspection, and significantly boosts production capacity.

Industry background

With the development of the food delivery industry, the demand for disposable chopsticks has significantly increased. Most production companies still rely on manual inspection for defects or traditional machine vision methods, which gradually fail to meet the precision requirements of the manufacturing industry and struggle with defect target detection.

In response to this industry challenge, Xinjie has introduced a bamboo chopstick sorting machine solution. This solution, centered on AI deep learning and using standard industrial cameras, allows for automatic, high-speed, and precise sorting of bamboo chopsticks. It offers high stability and efficiency, surpassing manual quality inspection, and significantly boosts production capacity.

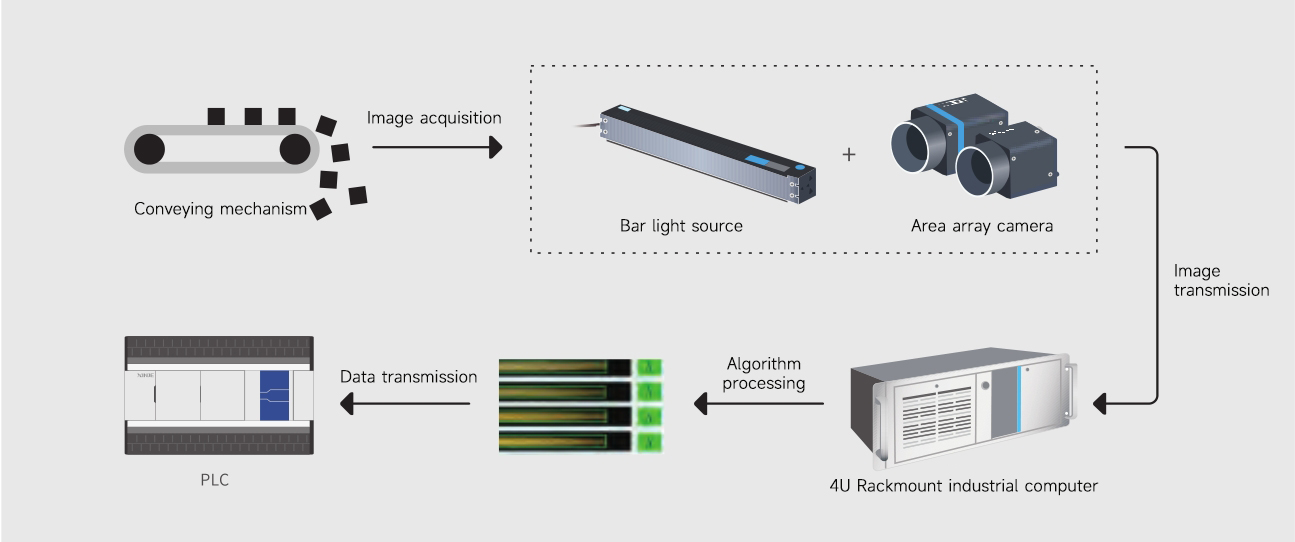

Control plan

The bamboo chopstick sorting machine solution mainly consists of an industrial computer, an industrial camera, and a PLC control system. After the camera captures images, they are transmitted to the host computer, which calculates defect results. The PLC compiles the results from eight operations, and then the corresponding compartment blows out the defective items, repeating the process continuously.