Lock and Hinge System Solution

Lock and Hinge System Solution

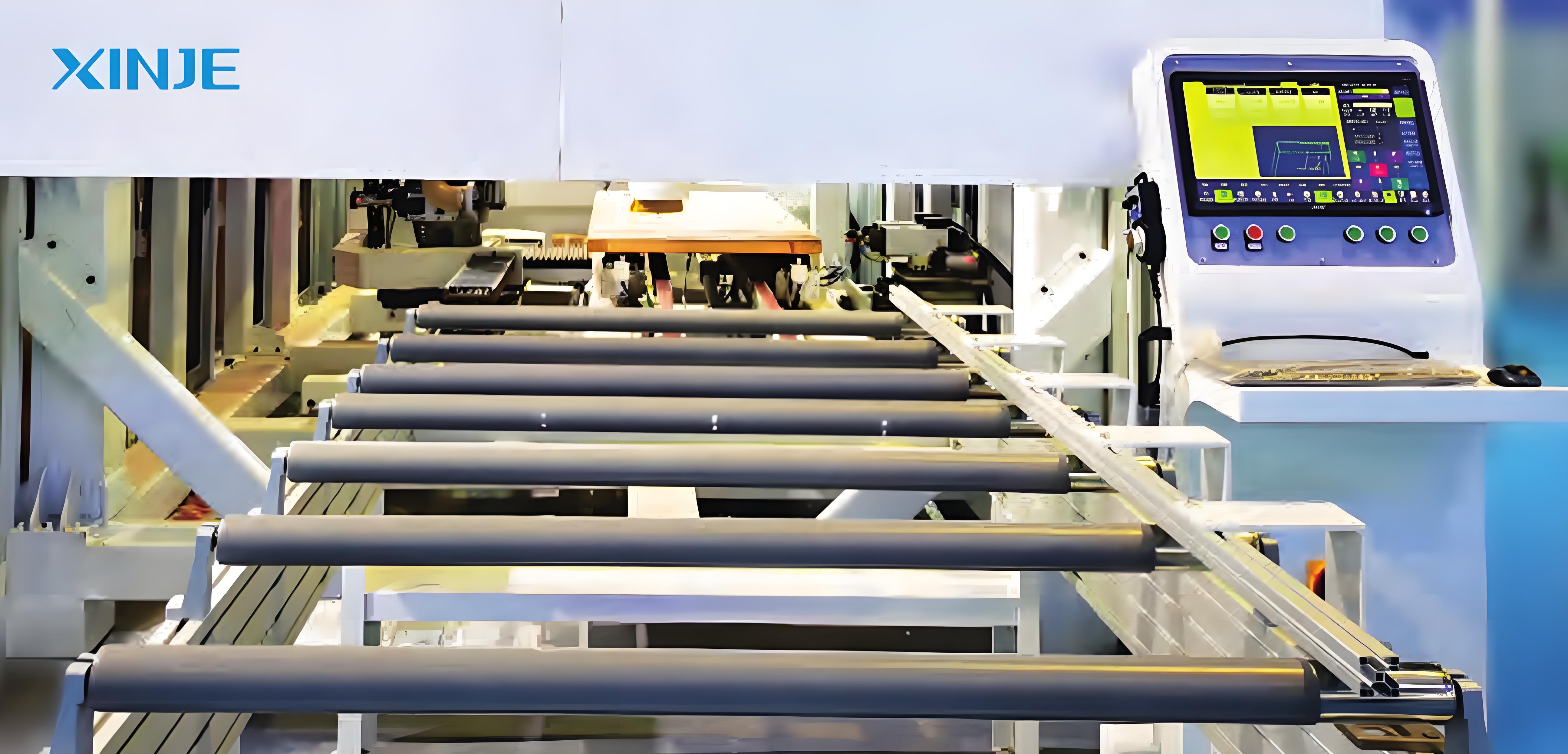

Exquisite craftsmanship and flexible manufacturing

Customizing solutions based on the specific needs of enterprises is the best approach for automated wood door manufacturing at this stage. This requires wood door manufacturers to adopt a systematic approach, standardized thinking, and modular design in product research and development to enhance the flexibility of equipment supply, shorten production cycles, and adapt swiftly to the changing custom demands of the market.

Industry background

Wood door companies face challenges in adopting a specific automated flexible production method for standardized manufacturing due to diverse end-user demands, varying production processes, different company sizes, and resource conditions. Therefore, tailoring solutions based on the specific needs of each enterprise is the best approach for automated manufacturing at this stage. This requires wood door manufacturers to employ a systematic approach, standardized thinking, and modular design in product research and development to enhance equipment supply flexibility, shorten production cycles, and swiftly adapt to the changing custom demands of the market.

Technological process

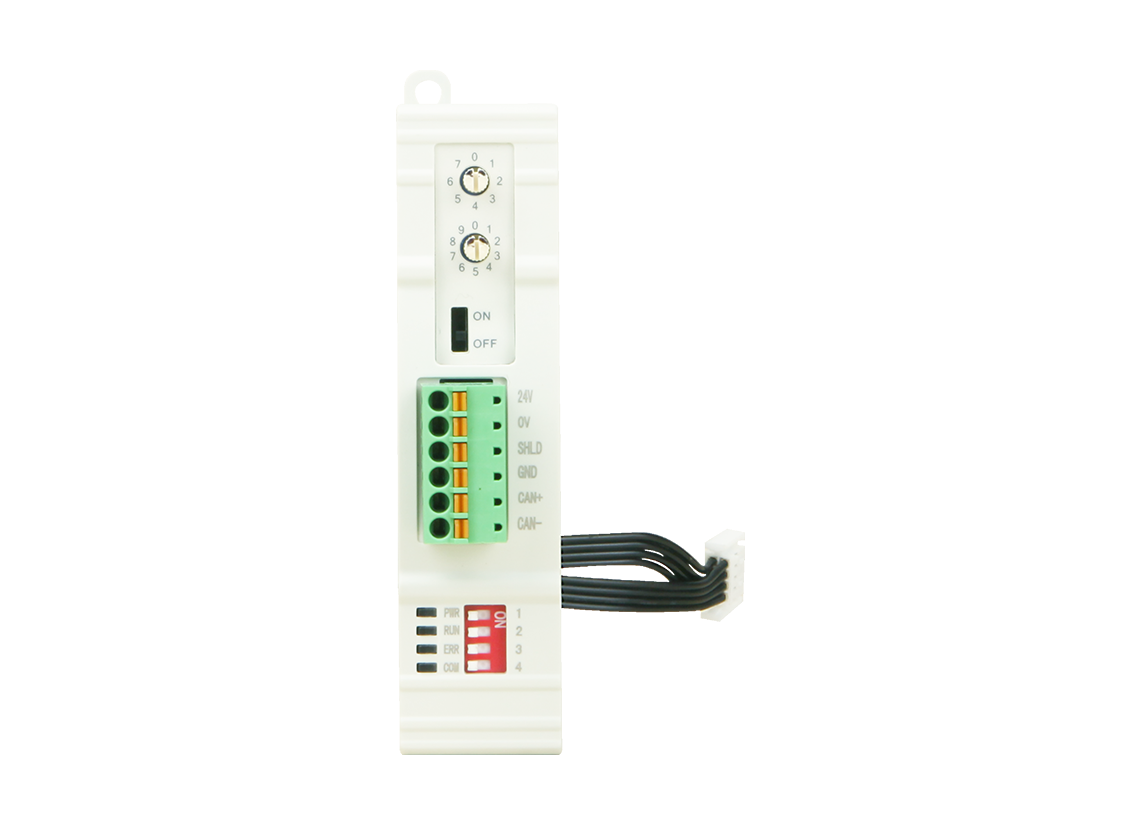

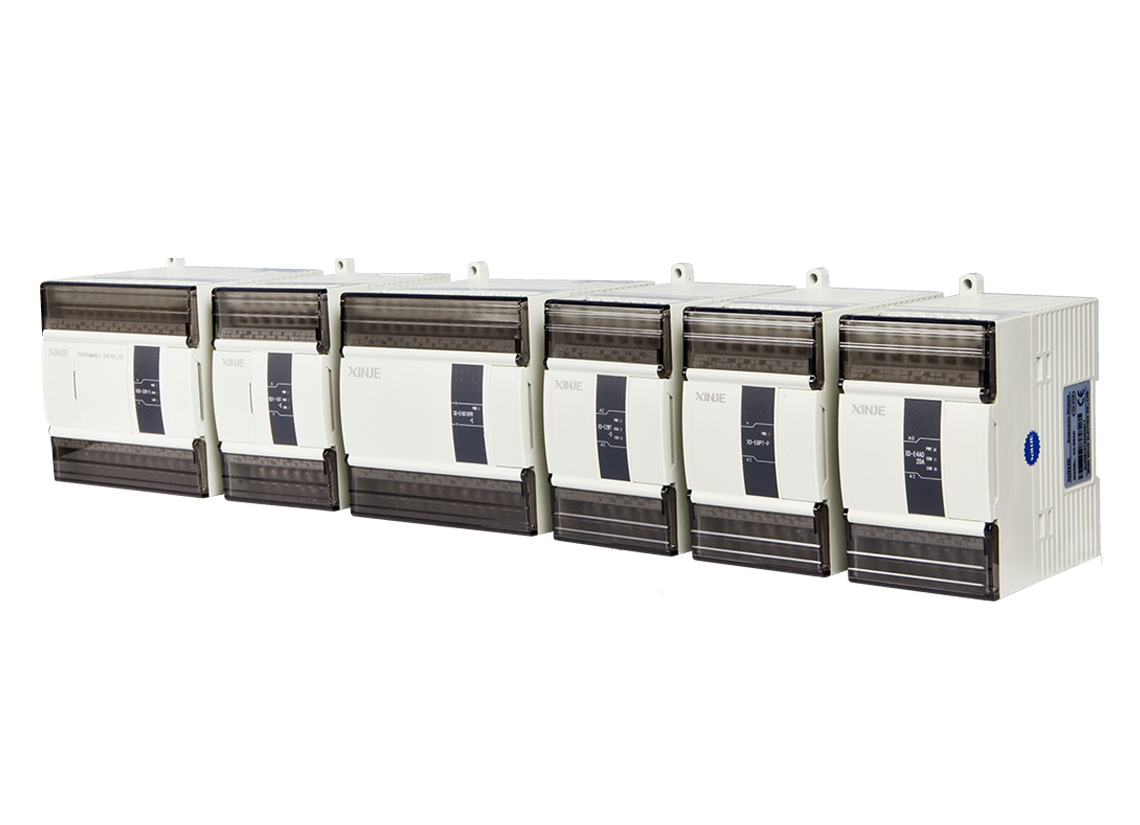

Control solution

The lock and hinge machining center consists of an industrial computer, a system controller, and a servo system, all interconnected via Ethernet for faster and more stable communication. It features three-stage control: face lock machining with pre-paint hole processing, lock and hinge machining, and post-paint hole processing. With a 5-channel interpolation and 16-axis control solution, the entire door can be processed in under a minute.