Solution for Double-headed saw for aluminum profiles

Solution for Double-headed saw for aluminum profiles

High precision and efficiency, reliable performance, advanced technology

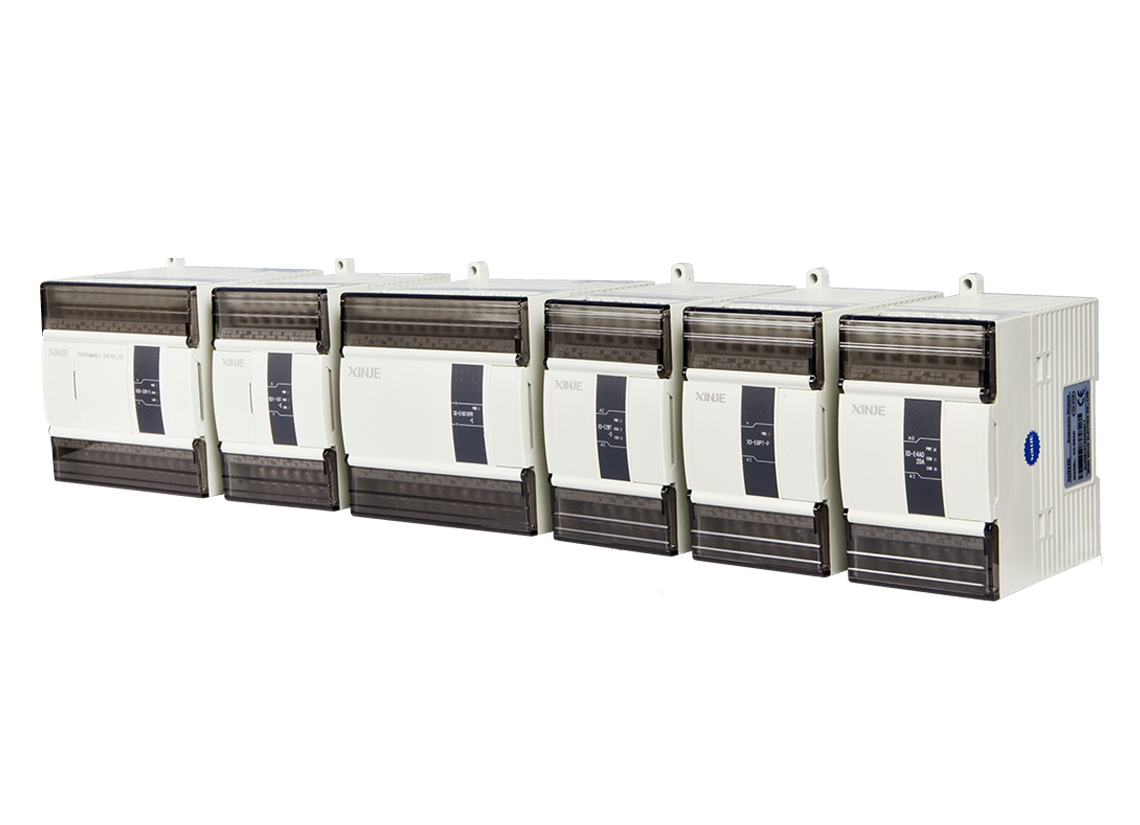

In order to adapt to the fiercely competitive market environment today and meet the requirements of low-cost, high-efficiency, diversity, and high precision for aluminum door and window processing equipment manufacturers, Xinje has launched various solutions, including sawing centers, sawing and milling centers, end milling, drilling and milling centers, aluminum door and window production lines, etc.

Industry background

Compared to plastic doors and windows and plastic steel doors and windows, aluminum alloy doors and windows have huge advantages. Moreover, aluminum alloy doors and windows have been developed in China for more than 30 years, and their product types and performance have been steadily increasing, gradually breaking the traditional market pattern of doors and windows. Especially in recent years, the total market volume of aluminum alloy doors and windows has increased sharply.

Nowadays, aluminum door and window processing equipment manufacturers have increasingly pursued low cost, high efficiency, diversity, and high precision. In order to adapt to the fiercely competitive market environment and meet the overall processing needs of aluminum doors and windows, Xinje Carving Industry Project Department has launched various solutions, including sawing centers, sawing and milling centers, end milling, drilling and milling centers, aluminum door and window production lines, etc.

System function

The control system adopts pulse servo drive control and is equipped with industrial computer loaded with upper computer software. In terms of software integration, it interfaces with window and door software manufacturers such as Xingeer and Changfeng through cloud-based interfaces, enabling various order placement modes such as online ordering and scanning code ordering. The system supports multiple machine models, including non-mitered inside mitered models, non-mitered outside mitered models, mitered inside mitered models, and mitered outside mitered models, offering flexible options. The processing modes support various cutting modes such as short material cutting, standard material cutting, long material cutting, and layout processing to meet the cutting needs for different material lengths. It is also equipped with printing function to automatically generate QR codes, providing processing information for subsequent end milling machines and drill milling machining centers.