Solution for Bag Spring Machine System

Solution for Bag Spring Machine System

High speed, efficient and stable production, flexible manufacturing for quick adjustment

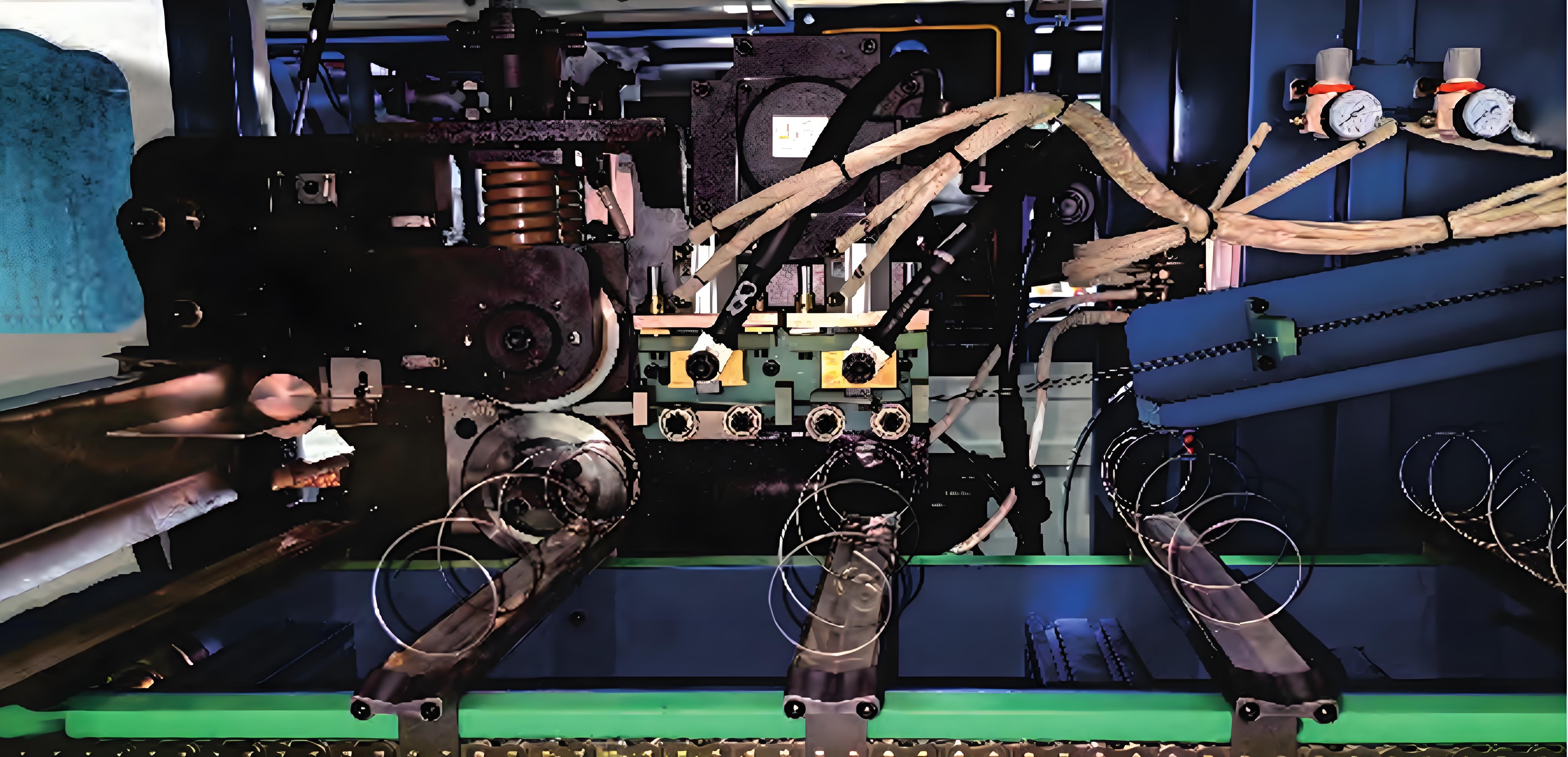

Early spring bagging machines were produced in conjunction with motors and cylinders, and the spring forming, conveying, and packaging actions only started after the previous action was completed, resulting in low production efficiency. The new model adopts an electronic cam control scheme, with reasonable planning of action coordination. Actions can be interspersed, effectively improving production efficiency. Moreover, a single model can quickly adjust electronic cam parameters to produce springs of different specifications.

Industry background

Spring machines mainly produce Simmons spring mattresses. With the improvement of living standards, people's requirements for furniture are gradually increasing, and furniture factories are gradually upgrading from price competition to quality competition.

Early spring bagging machines were produced in conjunction with motors and cylinders, and the spring forming, conveying, and packaging actions only started after the previous action was completed, resulting in low production efficiency. The new model adopts an electronic cam control scheme, with reasonable planning of action coordination. Actions can be interspersed, effectively improving production efficiency. Moreover, a single model can quickly adjust electronic cam parameters to produce springs of different specifications.

System principle

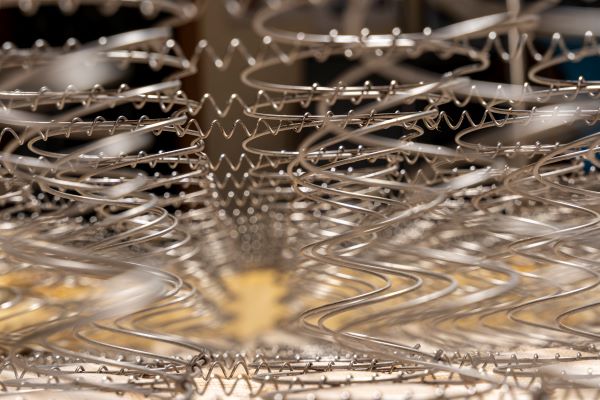

The self rotating wire feeder heats the steel wire, and the wire feeding wheel squeezes and bends the preheated steel wire through the machine head to produce springs. After being compressed by the packaging part, it is sent into non-woven fabric and ultrasonically welded into independent bagged springs, completing the spring components of the Simmons mattress. The action process is assisted by 10 servos. The spring forming is completed by the cooperation of the wire feeding motor and the forming shaft motor. The conveying motor sends the spring to the bagging position and completes the cooling and shaping. Then, the compression shaft and compression chain work together to compress the spring. Two small chains put the spring into the bag, and the non-woven bag is packaged by the large mold servo and small mold cylinder. The finished product is then sent out by the pull-down shaft.