Temperature control system - temperature homogenization solution

Temperature control system - temperature homogenization solution

Balanced heating, higher accuracy, and better control effect

Temperature homogenization control is achieved by controlling the heating rate of multiple temperature zones to avoid temperature overshoot and fluctuations. It can be applied in industries such as lithium battery vacuum ovens, wafer processing, photovoltaic sintering furnaces, photovoltaic drying furnaces, injection molding, compression molding, extrusion molding, and glass hot bending.

Industry background

Temperature is an important indicator in production processes. If the heating rate is not consistent, it will directly lead to temperature overshoot and fluctuations, which will affect the processing technology of the product and result in a decrease in yield.

Temperature homogenization control is achieved by controlling the heating rate of multiple temperature zones to avoid temperature overshoot and fluctuations. It can be applied in industries such as lithium battery vacuum ovens, wafer processing, photovoltaic sintering furnaces, photovoltaic drying furnaces, injection molding, compression molding, extrusion molding, and glass hot bending.

System principle

The temperature homogenization control technology effectively suppresses the mutual interference between adjacent channels by controlling the heating rate of multiple temperature zones, while ensuring that the temperature difference between each temperature zone remains unchanged throughout the heating process, achieving uniform heating of the controlled object and improving the processing quality of the product while reducing energy consumption.

Control solution

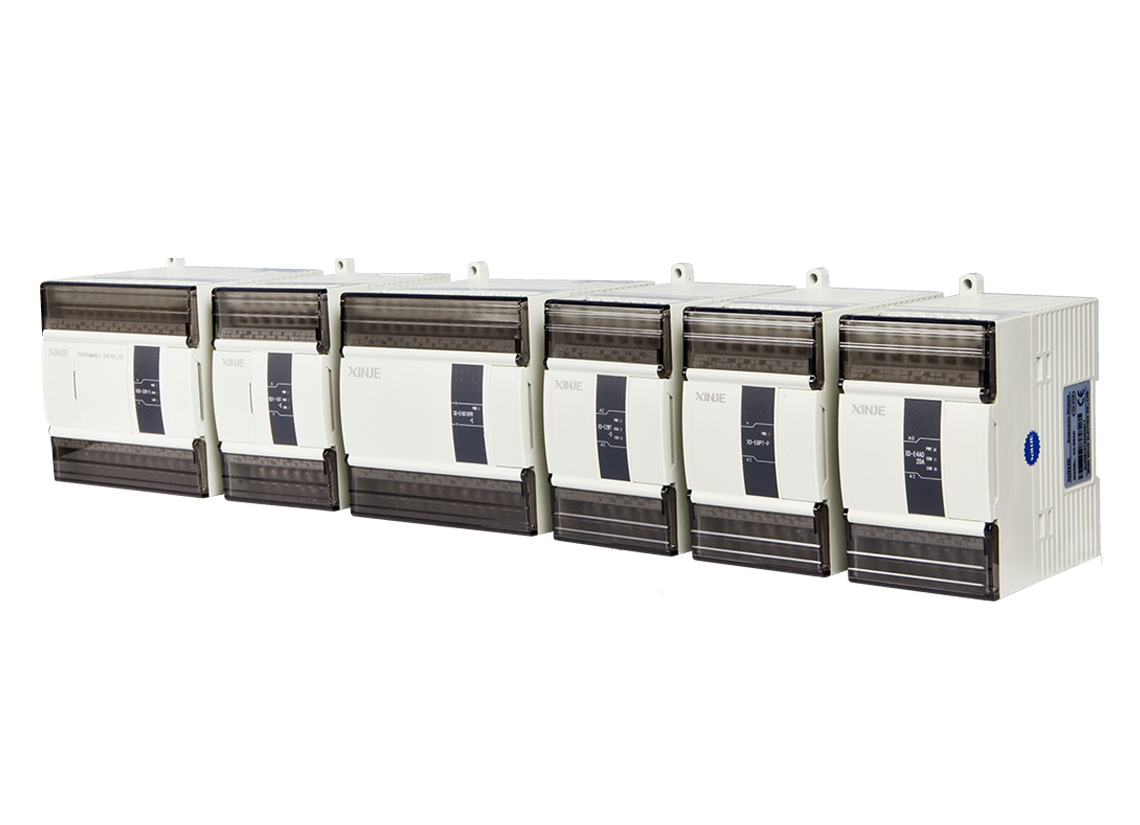

The temperature homogenization solution for the temperature control system is divided into two parts, including the homogenization decoupling and optimization part (process layer) and the PID control part (control layer). The PID control part easily ensures the processing speed. The homogenization decoupling and optimization part can ensure the uniformity of temperature coupling, including transient response, under the coupling effect of multiple temperature zones.

The entire solution adopts modular programming, which modularizes the homogenization process layer and PID control layer. The process layer can be flexibly matched with Xinje PID instructions to meet the needs of customers in different scenarios. The entire process has a short debugging time, and only simple settings are needed to achieve uniform parameters, easily solving the problem of uneven heating and achieving uniform heating speed in each temperature zone.

Solution advantages

Balanced Heating

Suppress Temperature Differences

Low Overshoot

Low Steady-State Error

High-Precision Temperature Control

More Convenient Debugging

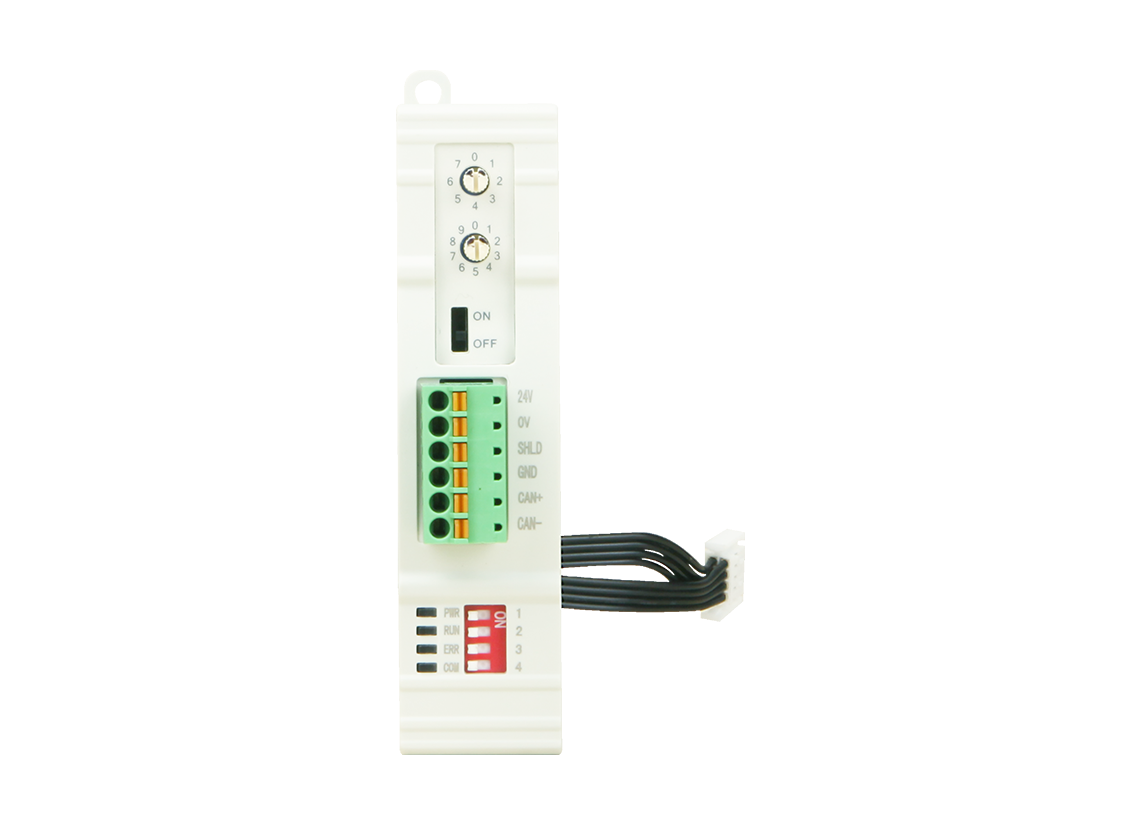

System topology