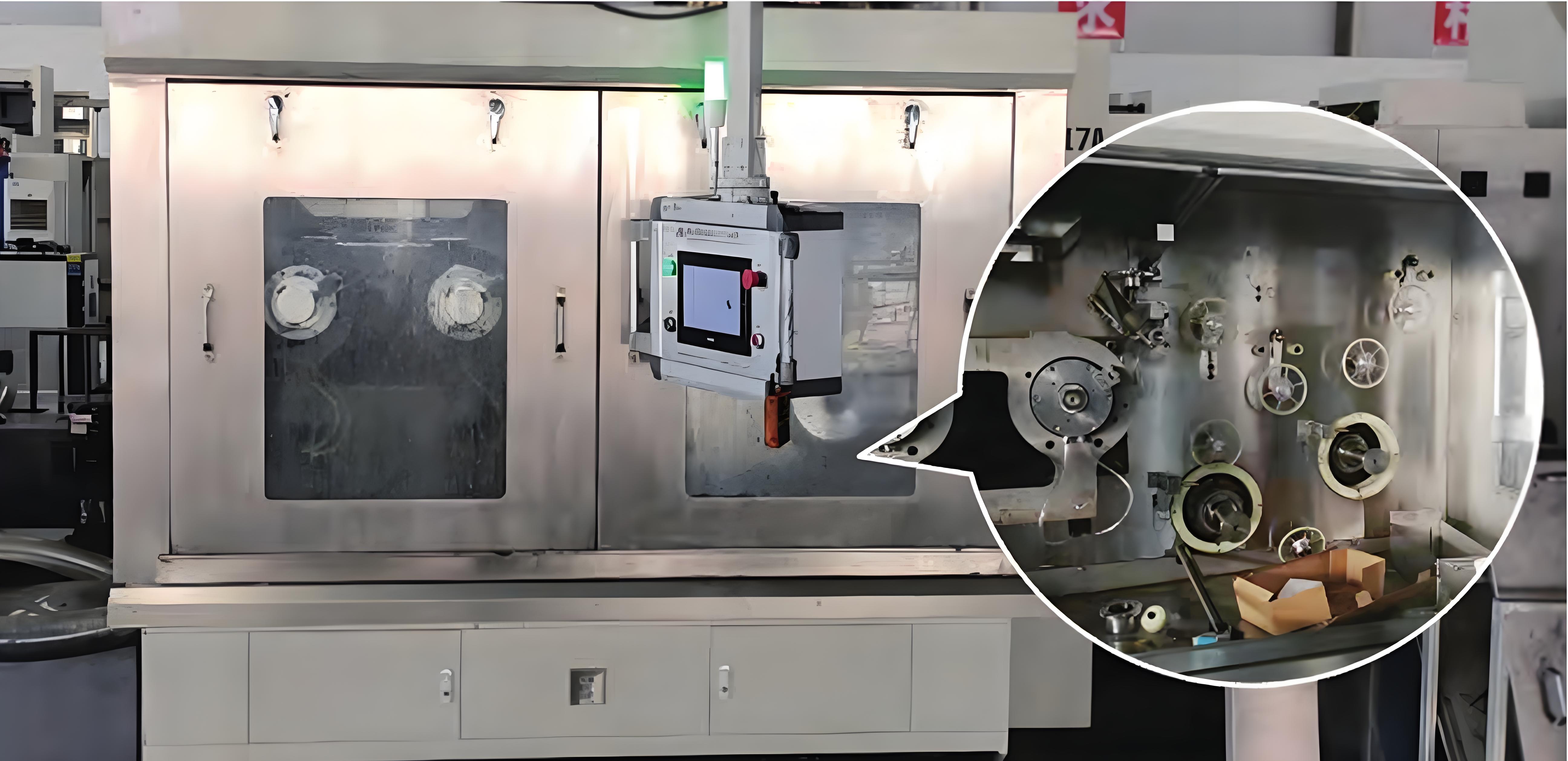

Solution for four spindle multi-thread cutting machine

Solution for four spindle multi-thread cutting machine

Higher precision, stable laying, and convenient operation

Multi-thread cutting machine is a key equipment in the manufacturing process of core device substrates in industries such as IC (integrated circuit), IT (information technology), PV (photovoltaic), etc. It has the advantages of high efficiency, high production capacity, and high precision, and is currently the most widely used equipment for cutting hard and brittle materials.

Industry background

Multi-thread cutting machine is a key equipment in the manufacturing process of core device substrates in industries such as IC (integrated circuit), IT (information technology), PV (photovoltaic), etc. Multi-thread cutting is currently the most advanced slicing technology. It is different from traditional cutting methods such as knife saw blades and grinding wheel blades, as well as laser cutting and inner circle cutting. Its principle is that the diamond thread forms a mesh on the main roller, and the material is cut into hundreds or thousands of thin slices through high-speed reciprocating motion. Multi-thread cutting technology has the advantages of high efficiency, high production capacity, and high precision, and is currently the most widely used cutting technology for hard and brittle materials.

System principle

The four spindle solution adopts four spindle fuzzy PID control to ensure torque stability between the four spindles. The retractable thread is controlled by PID feedback through the retractable thread swing rod, ensuring stable swing rod angle and online tension. The thread laying and releasing swing rod adopts the bus torque mode, which can conveniently and effectively modify the tension on the thread, and at the same time, perform closed-loop control with the tension sensor. Ensure stable online tension. The workbench adopts a formula scheme to meet the processing needs of customers for different materials. At the same time, it supports switching between straight tiles, making it convenient for customers to process tile straight needs. Tiles support single segment compensation, resulting in higher cutting accuracy.

Technological process

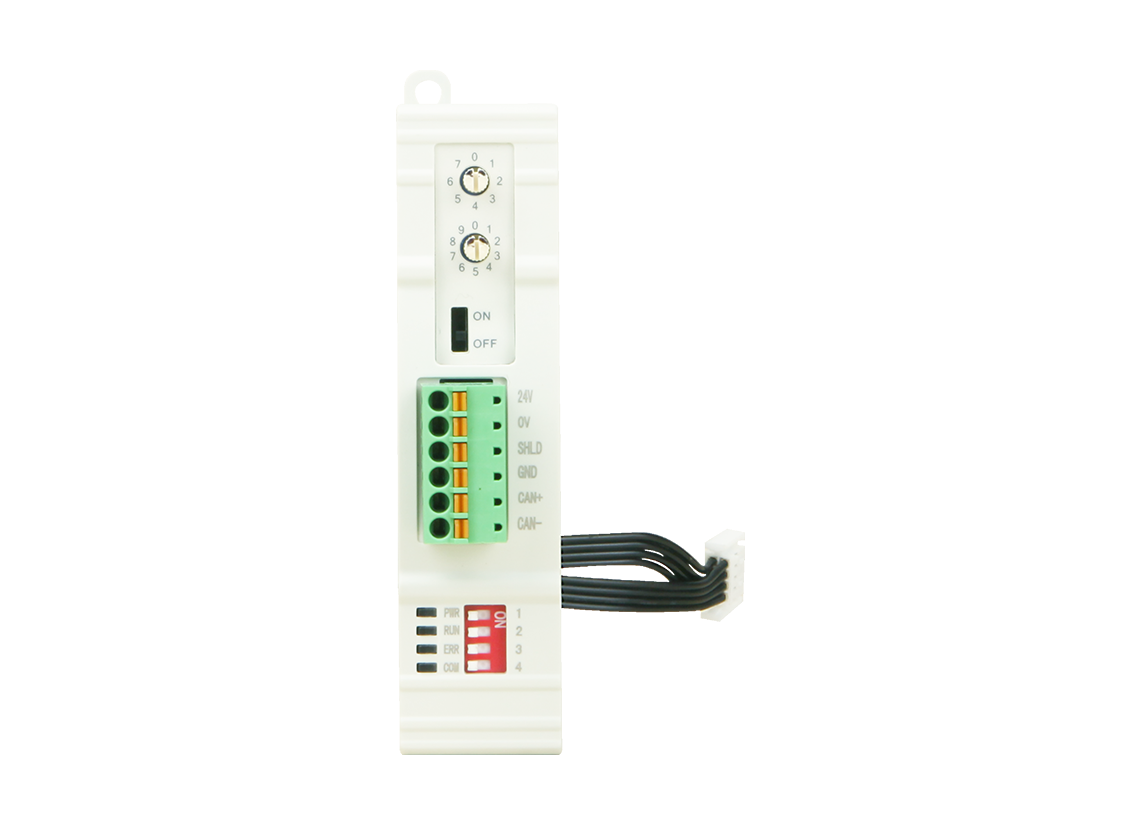

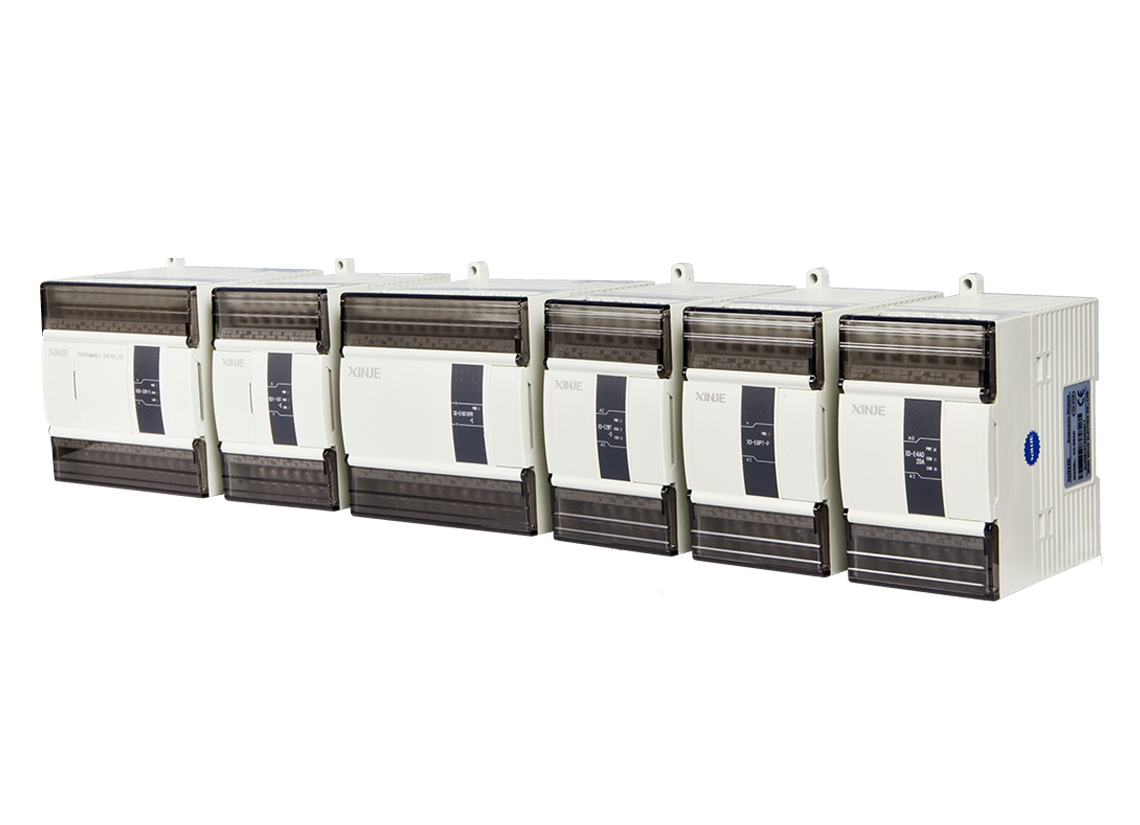

System topology