Industrial Sewing Industry Solution

Industrial Sewing Industry Solution

Flexible customization, high openness, and rich functions

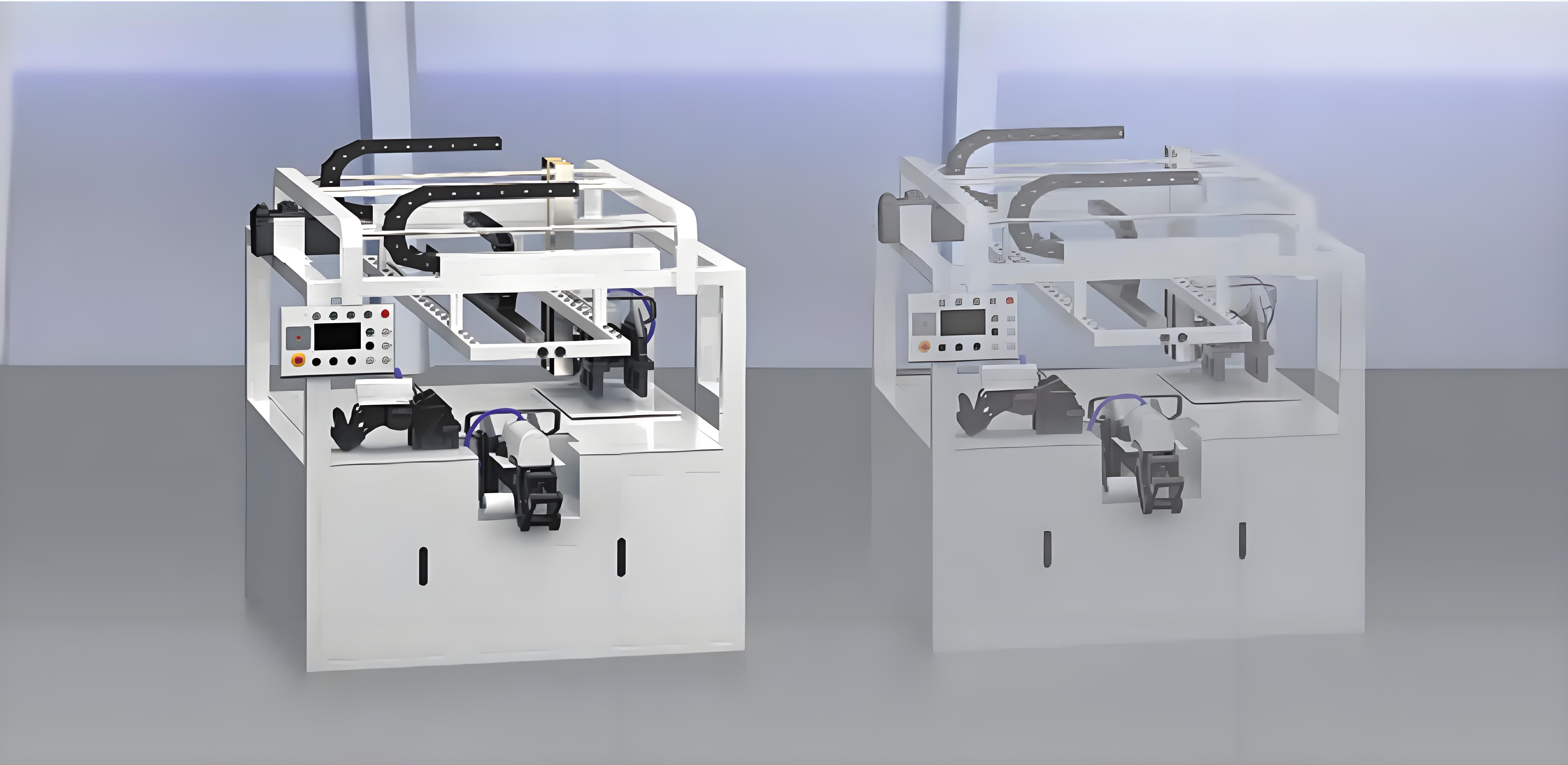

Xinje Sewing System is mainly applied to the models with industrial sewing machine heads such as flat sewing, overlock sewing, and overlock sewing as the needle shaft, supplemented by 1-4 axes movement for sewing cooperation. For example, flat cars (pattern machines, rotating machine head template machines, quilting machines, etc.), overlock (four-sided sewing), and non-standard sewing models on the market. Compared with the systems of other brands on the market, the Xinje system has many advantages such as stronger graphic compatibility, more convenient graphic import, and convenient secondary development, which can meet the advanced and rich customization needs of customers.

Industry background

Food, clothing, housing, and transportation are indispensable material needs in human society. When it comes to “clothing”, sewing will be associated. With the increasing demand for clothing and home textiles and the decreasing number of skilled workers, like other industries, the degree of automation in the sewing industry is continuously improving, and the domestic automatic sewing equipment has already been the world’s number one output.

The Xinje Sewing System is mainly applied to the models with industrial sewing machine heads such as flat sewing, overlock sewing, and overlock sewing as the needle shaft, supplemented by 1-4 axes movement for sewing cooperation. For example, flat cars (pattern machines, rotating machine head template machines, quilting machines, etc.), overlock (four-sided sewing), and non-standard sewing models on the market.

Compared with the systems of other brands on the market, the Xinje system has many advantages such as stronger graphic compatibility, more convenient graphic import, and convenient secondary development, which can meet the advanced and rich customization needs of customers.

Control plan

PLC (pulse, bus)+CAD system screen, touch all-in-one machine