Battery thermal management system BTMS

Battery thermal management system BTMS

Anti-vibration, high temperature resistance, stable and reliable

Energy storage, as a high-quality flexible resource, can provide various services such as peak shaving, frequency regulation, backup, black start, and demand response support for the operation of the power grid. It is an important means to enhance the flexibility, economy, and safety of traditional power systems.

Industry background

Energy storage is an important part and key supporting technology of smart grid, renewable energy high proportion energy system and "Internet plus" smart energy. Vigorously developing energy storage is a necessary option to improve the utilization rate of renewable energy and achieve the "dual carbon" goal. Energy storage, as a high-quality flexible resource, can provide various services such as peak shaving, frequency regulation, backup, black start, and demand response support for the operation of the power grid. It is an important means to enhance the flexibility, economy, and safety of traditional power systems.

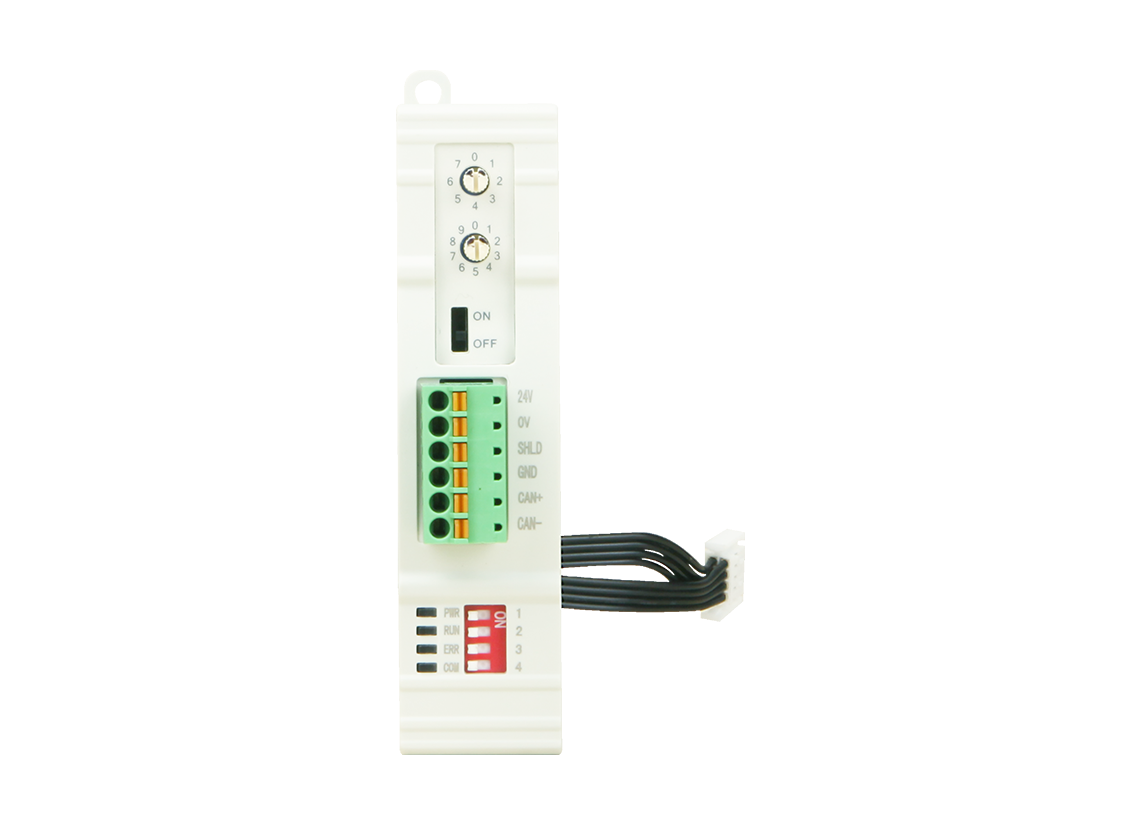

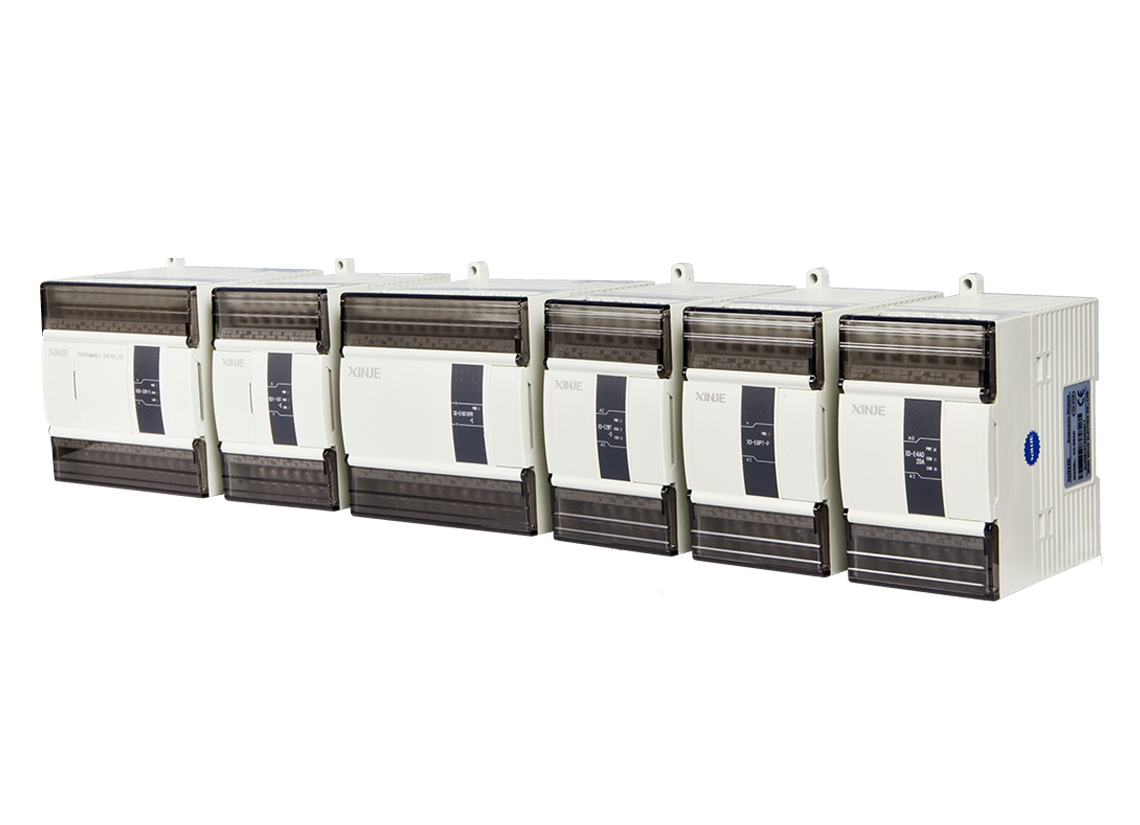

The Xinje Energy Storage EMS controller includes rich interfaces, vehicle grade controllers, and is designed for seismic and high-temperature applications. It can adapt to harsh environments such as large-scale temperature changes, intense vibrations, and strong electromagnetic interference, providing a reliable working environment.

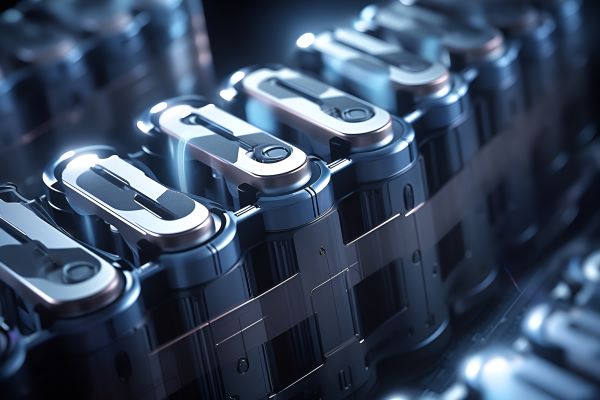

Process principle

Lithium batteries or other types of batteries show different performance depending on the ambient temperature during operation. For example, when the temperature is too low, the battery life will be shortened and the working time will be reduced. When the temperature is too high, the battery will also emit heat, and there is a risk of spontaneous combustion when reaching a certain temperature. At this point, a Battery Thermal Management System (BTMS) is needed to heat or cool the battery.