Screw lock industry solution

Screw lock industry solution

High speed, efficient, precise and complete

The use of automatic screw locking equipment can greatly improve production efficiency and reduce labor costs, and can achieve long-term and efficient non-stop operations. It is one of the most important links to achieve a "black light automatic factory".

Industry background

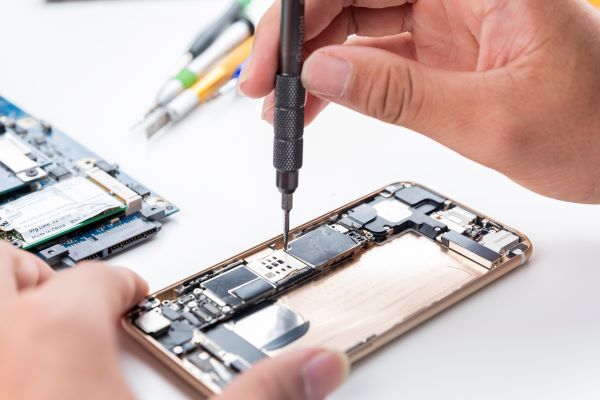

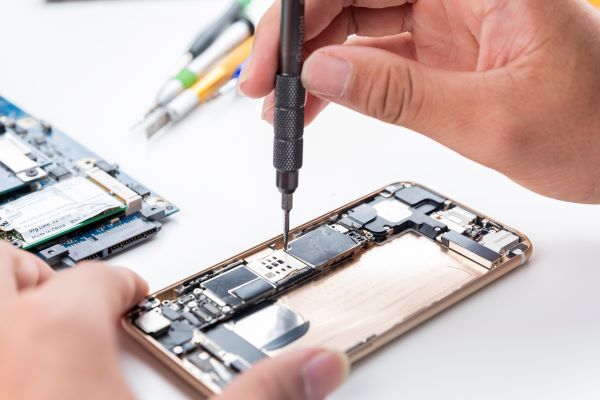

For a long time, in many traditional labor-intensive enterprises, assembly operations have mostly relied on manual labor, with one hand holding the electric or pneumatic screwdriver and the other hand grasping the screws and aligning and locking them. Each screw requires a significant amount of time spent on actions such as grabbing, moving, waiting, and aligning, and there is a high demand for screw stations on each production line, resulting in a sharp increase in labor and management costs.

The use of automatic screw locking equipment can greatly improve production efficiency and reduce labor costs, and can achieve long-term and efficient non-stop operations. It is one of the most important links to achieve a "black light automatic factory".

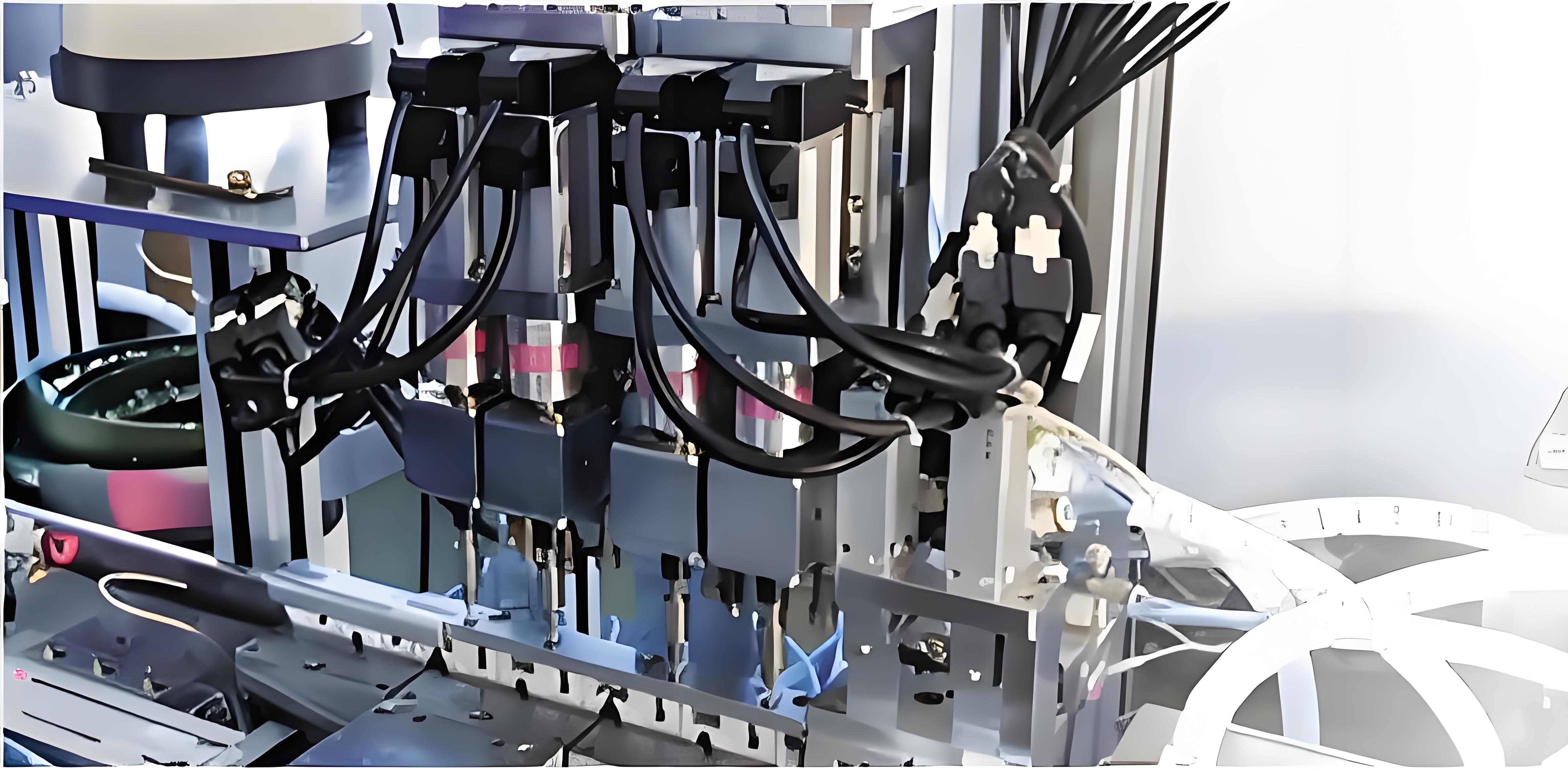

Process principle

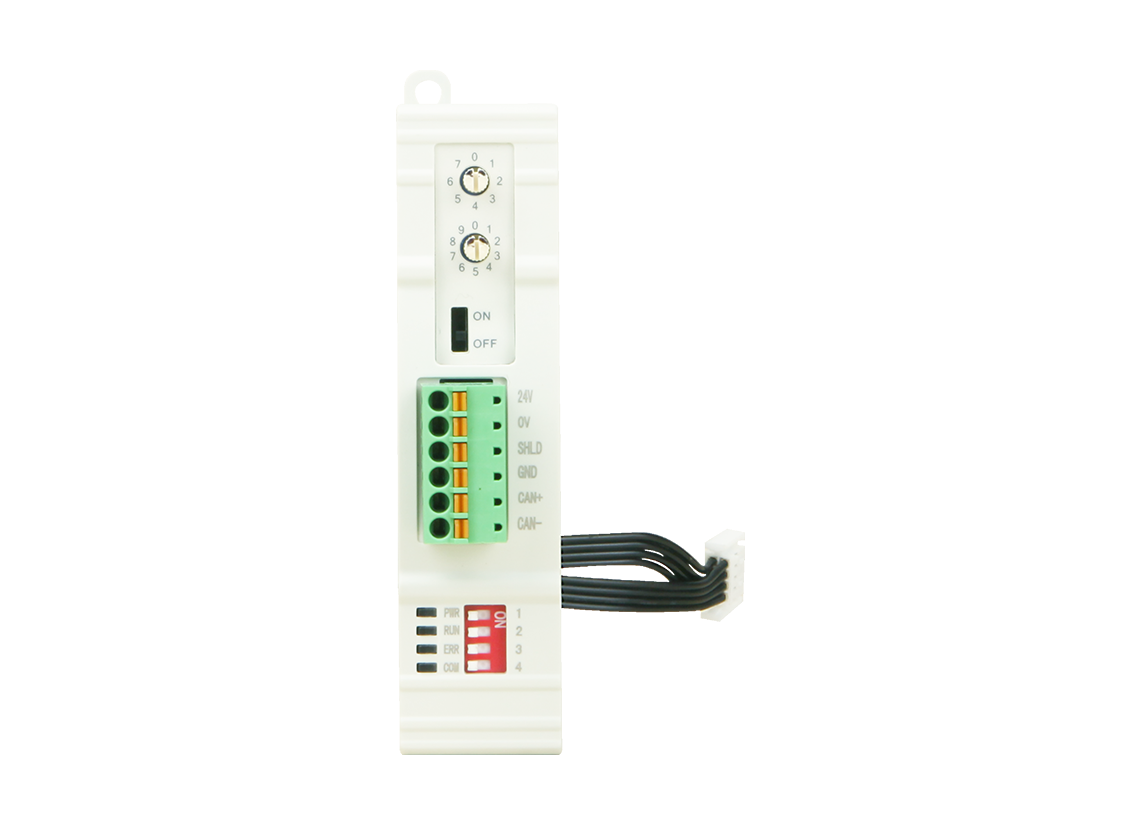

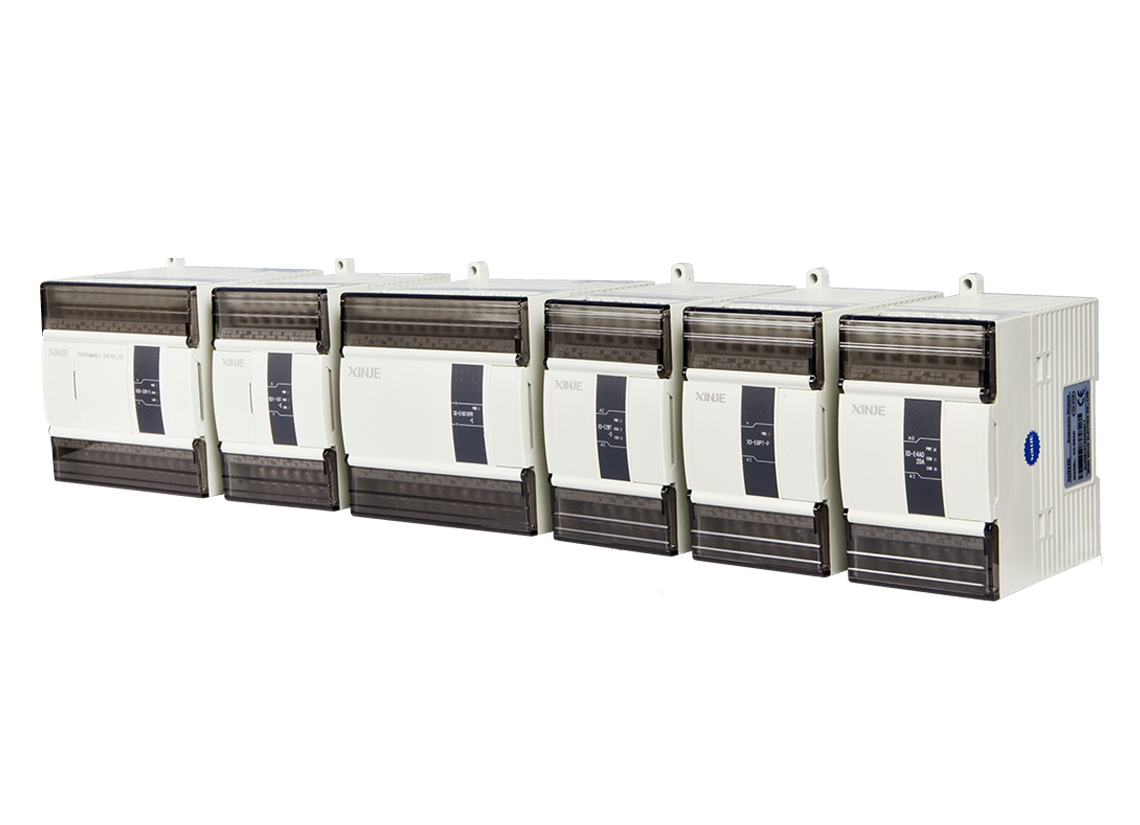

System topology

The overall solution is complete and efficient, providing a complete set of products for management, control, perception, and execution layers, including PLC, HMI, industrial computer, stepper, servo, vision, robot, and supporting software.