Automatic Filling Machine System Solution

Automatic Filling Machine System Solution

Precise Quantification, Multi-Functional Machine, Easy Operation

Quantitative weighing primarily targets industry sites where packaging control is required by weight. It can be widely applied in sectors such as food, feed, seeds, chemicals, and pharmaceuticals, including but not limited to packaging machines, mixers, batching machines, and filling machines.

Equipment introduction

Automatic filling involves quantitatively packaging liquid materials. For manufacturers, quantitative filling is the final step before products leave the factory and is crucial for ensuring uniform product specifications.

Traditional filling machines struggle with precise quantification, but weigh-based automatic filling offers fast filling speeds and is unaffected by the liquid level and pressure in storage containers. It is now widely used in filling lubricants, edible oils, and beverages.

Operating principle

The automatic weighing and filling machine primarily consists of a storage tank, feed pipeline, weighing chamber, filling head, and automatic conveying device.

The storage tank is used for storing the liquid materials to be filled. The feed pipeline connects the storage tank to the weighing chamber, where the liquid's weight is precisely controlled. Finally, the filling head delivers the liquid into containers brought by the automatic conveying device, completing the filling process.

Most automatic weighing and filling machines can be classified into 1-12 channel machines based on actual needs. Depending on the weighing method, they can further be divided into top weighing and bottom weighing types.

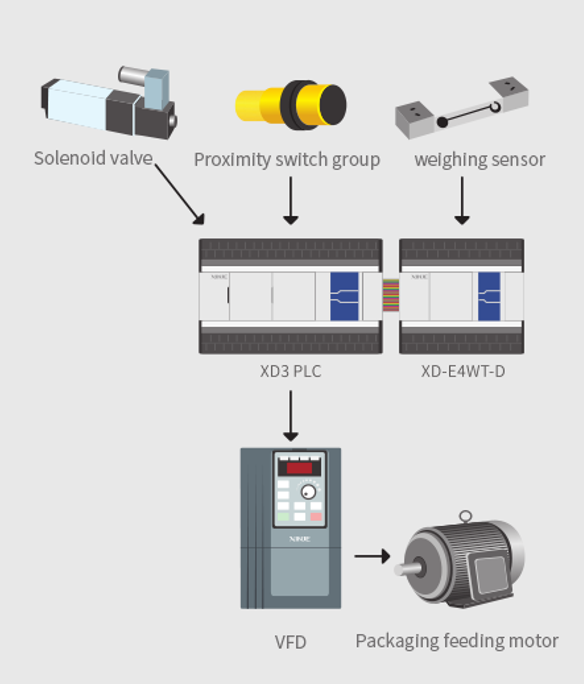

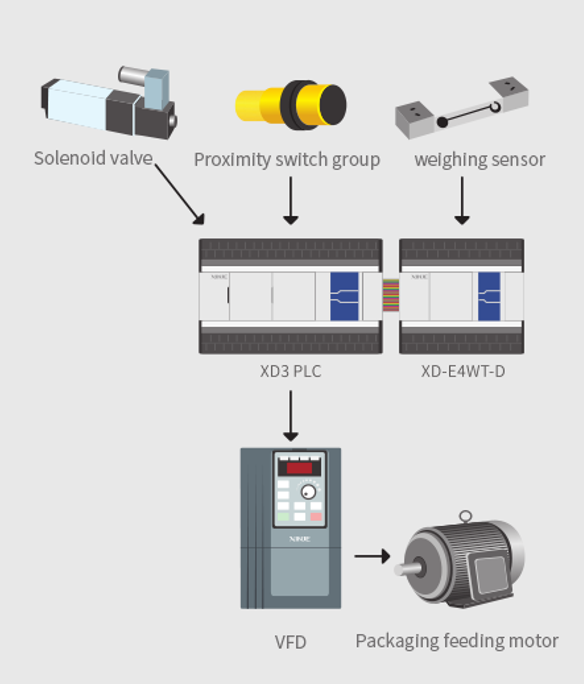

System topology

The solution utilizes the Xinje XD series PLC and XD-E4WT-D weighing system, driven by a frequency converter. It features high integration, strong control capability, and reliable operation. By applying Xinje touchscreen technology, the machine's operation becomes more reliable and convenient, enhancing the user interface. With the use of load cells, photoelectric sensors, encoders, etc., the automatic filling machine solution is excellently realized.