Pillow packaging machine system solution

Pillow packaging machine system solution

High speed smooth operation, simple operation, flexible and efficient

The traditional pillow packaging machine's horizontal sealing knife motion curve is achieved by a mechanical cam, which is complex to install, has high operating noise, is difficult to adjust, and has low efficiency. The Xinje pillow packaging machine system covers high-speed, stable and smooth operation of the belt and ruler tailstock, with fixed length, fixed mark and non fixed length packaging, including functions such as anti-empty bag, torque anti-cutting material, photoelectric anti-cutting material, etc.

Industry background

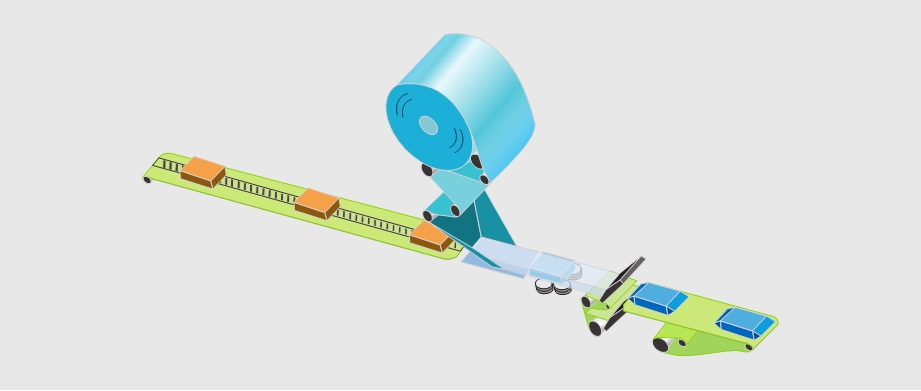

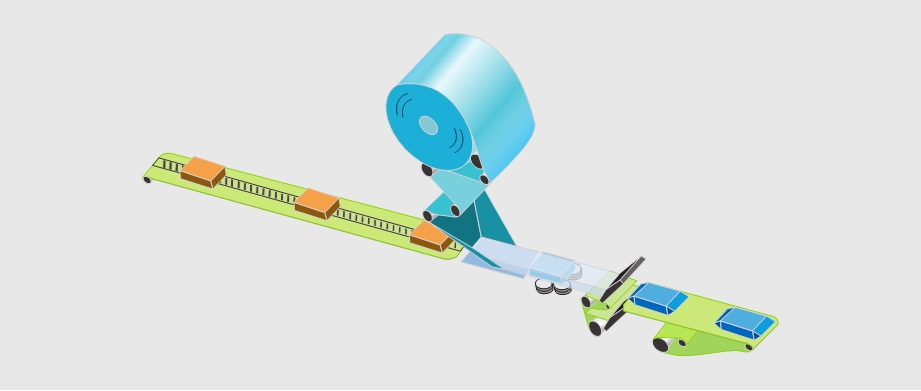

Pillow packaging machine is a horizontal three sided sealing equipment that can complete processes such as bag making, filling, sealing, cutting, and finished products. It is widely used in automated production lines for food, hardware, daily chemical, pharmaceutical and other industries for flow packaging. Suitable packaging materials are generally block shaped or cylindrical regular items, such as cookies, cakes, noodles, cosmetics, tissues, etc. The packaging machine for the belt tail frame can package products of varying lengths, such as bread, electrical conduits, and other products.

System principle

The film and material feeding of the pillow packaging machine are synchronized, and the position of the feeding is detected by color code detection and proximity switch respectively. The film is formed into a cylindrical film by the forming machine and undergoes longitudinal heat sealing. At the same time, the material is fed into the cylindrical film and passes forward through the transverse sealing cross section. The cylindrical film is horizontally sealed and cut by a rotary or reciprocating transverse sealing cross cutting knife, and the packaged product is output.

The film feeding axis needs to pass through a bag length for each rotation of the horizontal sealing knife axis, and the feeding film axis needs to deliver one piece of material. This process requires the three axes to remain synchronized at all times. The most important thing is that the speed of the horizontal sealing blade axis at the moment of sealing must be consistent with the speed of the plastic film, otherwise it may cause the plastic film to break or pile up during horizontal sealing.

System function

Stronger system stability and anti-interference ability

Anti-empty bag function

Optoelectronic anti-cutting function

Electronic cam function

Electronic cam features

Solution advantages

Automatic Level Calculation

No Mechanical Adjustment Needed

Electronic Cam with High Flexibility

Pulse + EtherCAT Bus Dual Solution

High Precision

System topology