Solution for tissue secondary packaging machine

Solution for tissue secondary packaging machine

High stability, increased production capacity, and enhanced flexibility

This machine is used for secondary packaging of single tissue, and the packaged paper has the advantages of product beauty, easy carrying, and further protection of small pack tissue. With the rise of online shopping, the demand has further increased. Xinje has developed an EtherCAT bus control solution for this market, which has the characteristics of high stability, increased production capacity, and enhanced equipment flexibility.

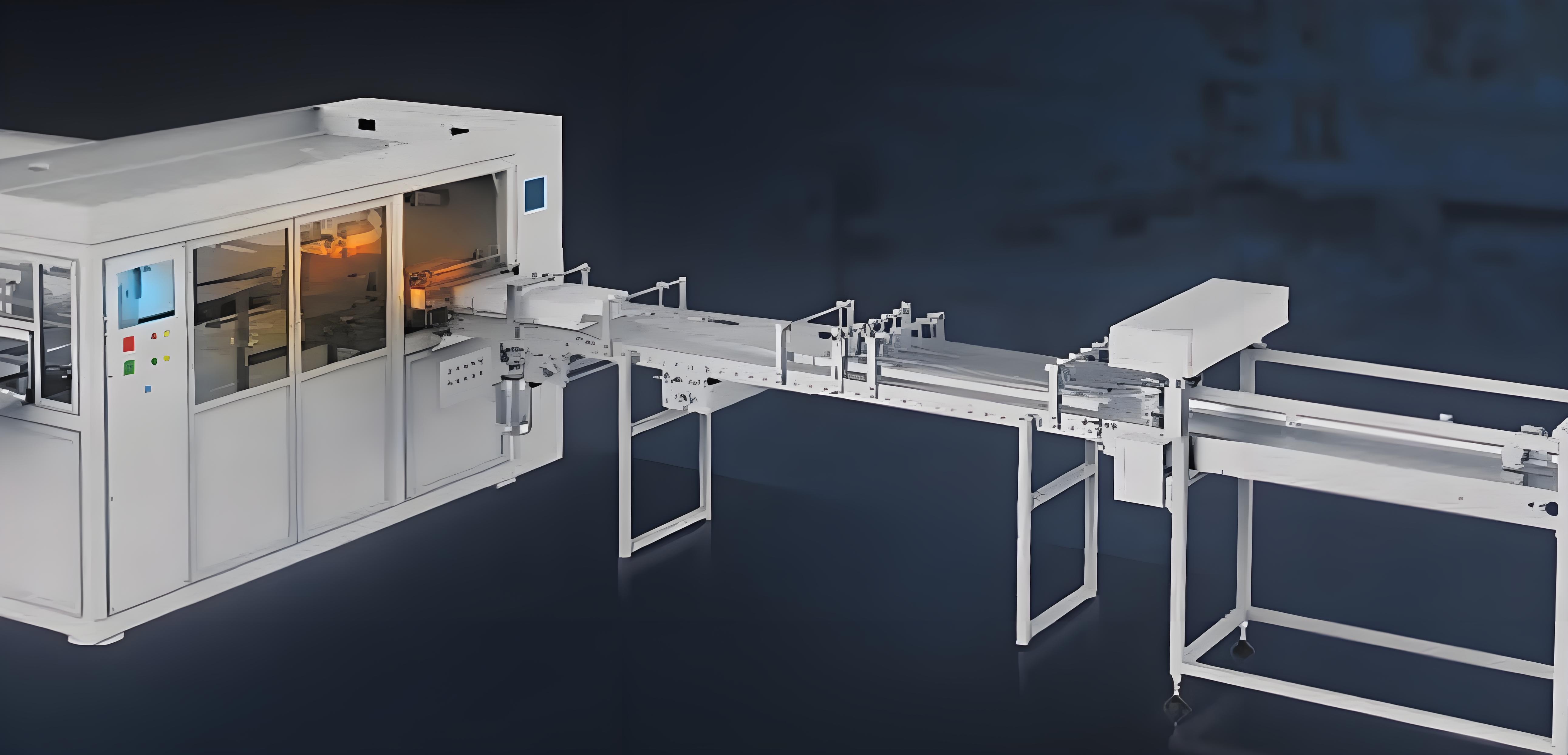

Equipment introduction

Tissue secondary packaging machine consists of one separation six material handling, lever, bag retrieval, bag delivery, bag opening, bag support, and left and right push heads. The system has protection functions such as bag delivery failure detection and bag support failure detection.

Equipped with 6-channel material handling function, it can enable 1-6 channels at will, intelligently allocate materials, and ensure continuous production in the subsequent channels.

Dual channel push head, alternating between pushing and homing, significantly improves the overall production efficiency of the equipment.

A series of intelligent alarm detection systems, such as bag support failure, material pressing, lifting timeout, and bag retrieval failure, can quickly identify and restore production.

Control solution

The system adopts multi-turn absolute encoder servo, which homing accurately and quickly, avoiding mechanism interference caused by fault homing. And each axis has interference protection to prevent mechanical impact.

The electronic cam curves of each axis are automatically generated internally, and the speed and timing of each axis action can be easily set. During operation, parameters such as bag feeding length, bag picking position, bag opening height, bag support position, and push head position can be changed.

It has a single step debugging function, allowing for independent actions such as bag retrieval, feeding, opening, and supporting. After changing specifications, it can quickly test whether the execution position is correct. The system has a whole machine jog function, which can avoid mechanical impact during the debugging phase.