SCARA robot vision top bottom cover fitting system solution

SCARA robot vision top bottom cover fitting system solution

Focused on the industry for over 10 years, faster, more accurate, and more stable

The traditional way of fitting the top and bottom cover is done manually, which is inefficient, has poor real-time performance, and unstable quality. The Xinje top bottom cover fitting system adopts independently developed SCARA robotic arm and vision system, which has the characteristics of high fitting accuracy, good stability, and strong applicability.

Industry background

With the rapid development of China's packaging industry, especially in recent years, the speed of development has been continuously accelerating. However, most packaging companies in China still use manual box pasting production methods, which require human observation or specific indentation to stick the top and bottom covers to the outer packaging surface paper.

This method has high manual labor intensity, low fitting efficiency, poor real-time performance, and is easily influenced by subjective factors, making it difficult for packaging products to meet today's market requirements. In response to the current industry situation, Xinje Company has independently developed a SCARA robotic arm combined with a visual system, achieving complete robot "hand" and "eye" coordination. Through the rapid positioning of the "eye" and the sending of execution commands through the "brain", the "hand" can quickly fitting the boxes. So as to truly replace traditional manual box fitting.

Control solution

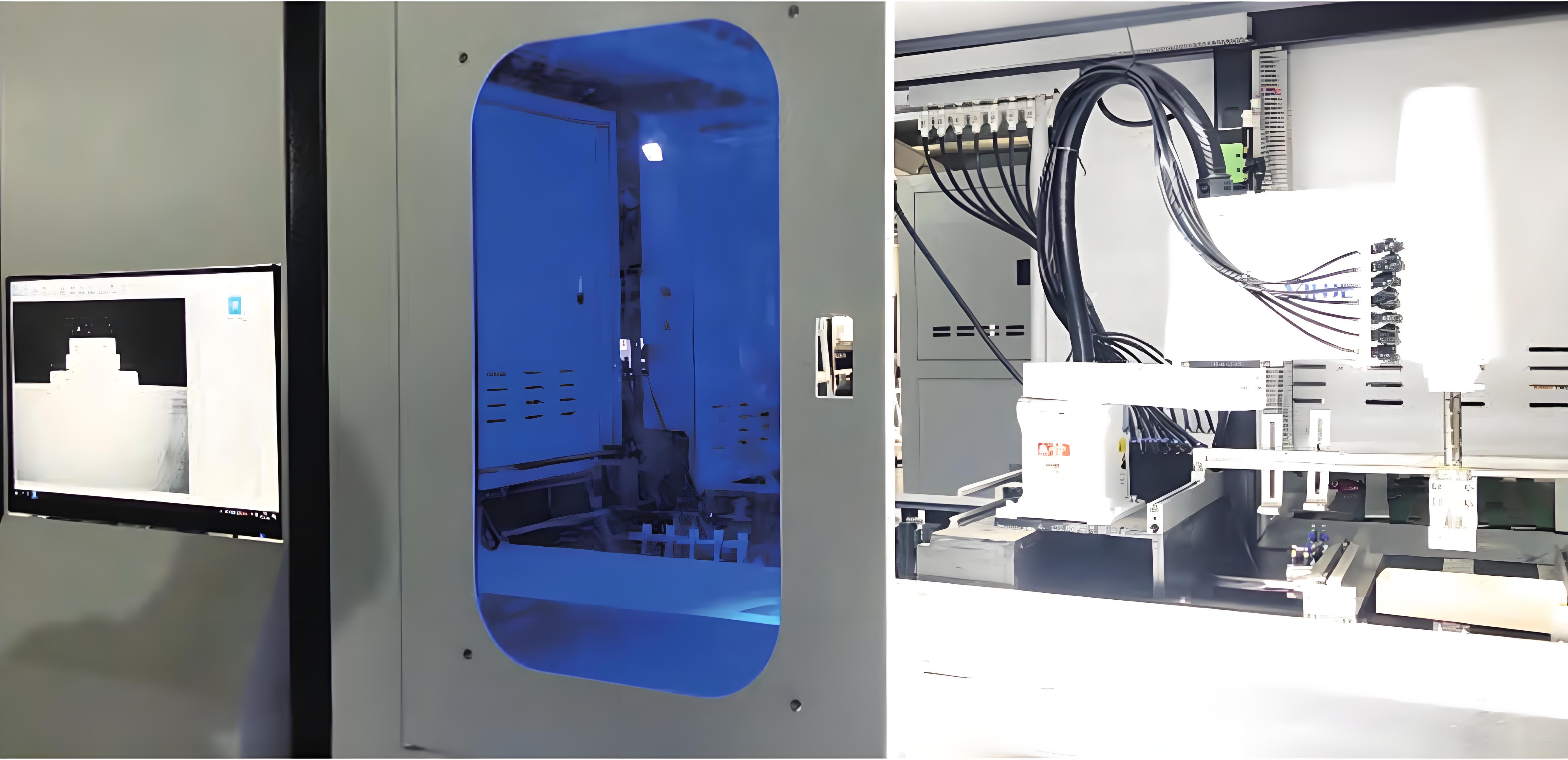

The SCARA robot vision cover fitting system independently developed by Xinje Company mainly consists of a single camera, an industrial computer, and a SCARA robotic arm system, which statically guides the robotic arm to locate and grasp targets through the vision system. The photoelectric sensor detects the target in place, the belt stops conveying, the camera locates the target based on external signals, the PC system performs image contour matching to recognize the current position of the target, and then transmits the position of the target to the robotic arm system to achieve static fitting.