Weighing industry solutions

Weighing industry solutions

Quantitative precision, multifunctional, easy operation

Quantitative weighing primarily targets industries where weight-based control is essential for packaging processes. It can be widely applied in sectors such as food, feed, seeds, chemicals, and pharmaceuticals. This includes, but is not limited to, usage in packaging machines, mixers, batching machines, and filling machines.

Industry background

Quantitative weighing primarily targets industries where weight-based control is necessary for packaging processes. The system collects real-time weight data to control graded feeding, and once feeding is complete, it proceeds to packaging or mixing and other subsequent operations. Quantitative weighing can be widely applied in sectors such as food, feed, seeds, chemicals, and pharmaceuticals, including, but not limited to, packaging machines, mixers, batching machines, and filling machines.

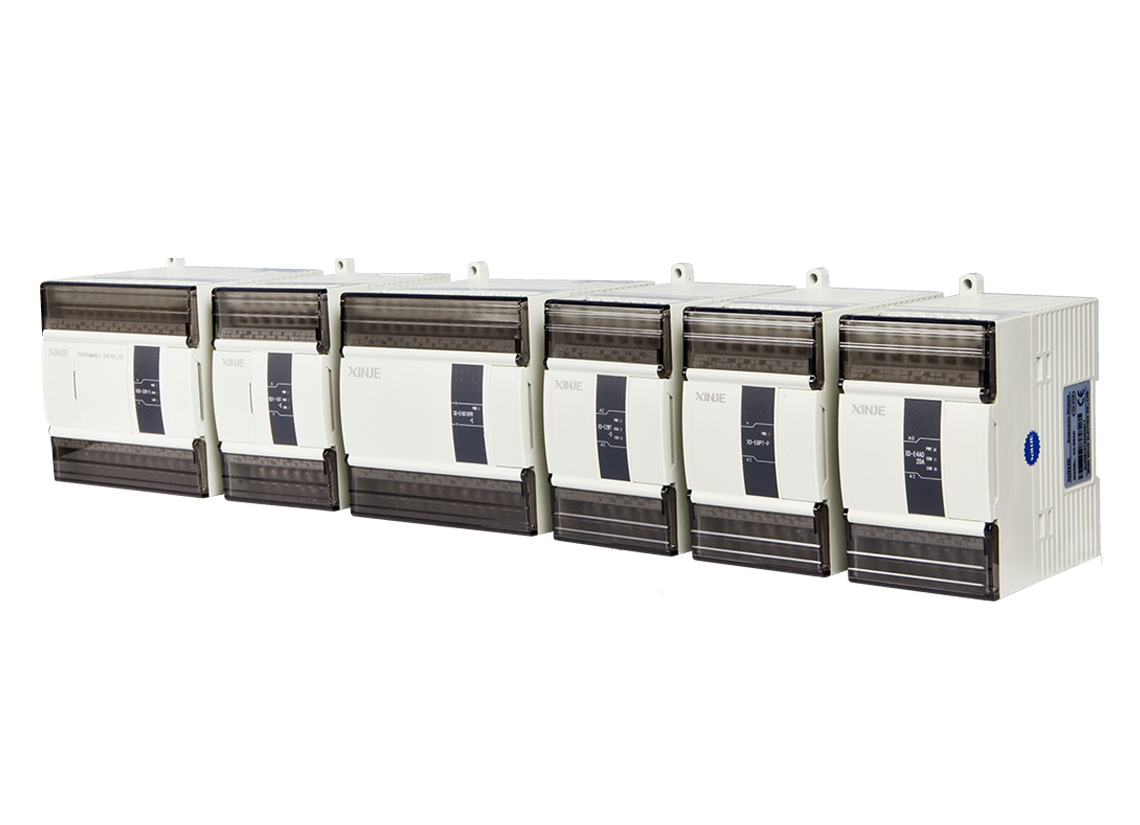

Equipment introduction

The CZ-130-A1/A2 Weighing Integrated Machine can be applied to quantitative packaging machines, which have a broad market in China. Based on different feeding methods, they can be divided into vibrating feeder, screw feeder, belt feeder, etc. The weighing integrated machine executes the feeding process in multiple graded stages: fast, medium, and slow feeding are clearly distinguished, with multi-stage operation.

System function

Optional single/dual scale controller based on actual needs.

Advanced modern high-precision multi-digital filtering.

7-inch full-color touchscreen display.

Fully automatic, with multiple selectable feeding control modes.

Parameter design in list format, intuitive and elegant.

Supports various equipment types such as hopper scale, non-hopper scale, ton bag scale, and valve bag scale.

USB interface, supports packaging data storage and export via USB drive.