Tubular twister system solution

Tubular twister system solution

Infinite speed regulation, consistent wire arrangement, higher precision, energy-saving and consumption reduction

A stranding machine is a device that twists several metal wires into a strand with a specific pitch and direction. The product, steel wire rope, is widely used in various industries and fields such as tires, metallurgy, shipping, elevators, cable cars, mining, marine, bridges, military, and aerospace.

System principle

A tubular stranding machine consists of one or more cylinders. The spools are arranged in a straight line along the center inside the machine. The cylinders rotate at high speed in conjunction with the traction device, causing the wires to wrap in a helical pattern and move linearly, forming strands with a specific twist pitch, thereby completing the basic stranding process, suitable for most rope strands. It mainly consists of the pay-off drum section, traction section, tension balance arm, take-up, and traverse sections.

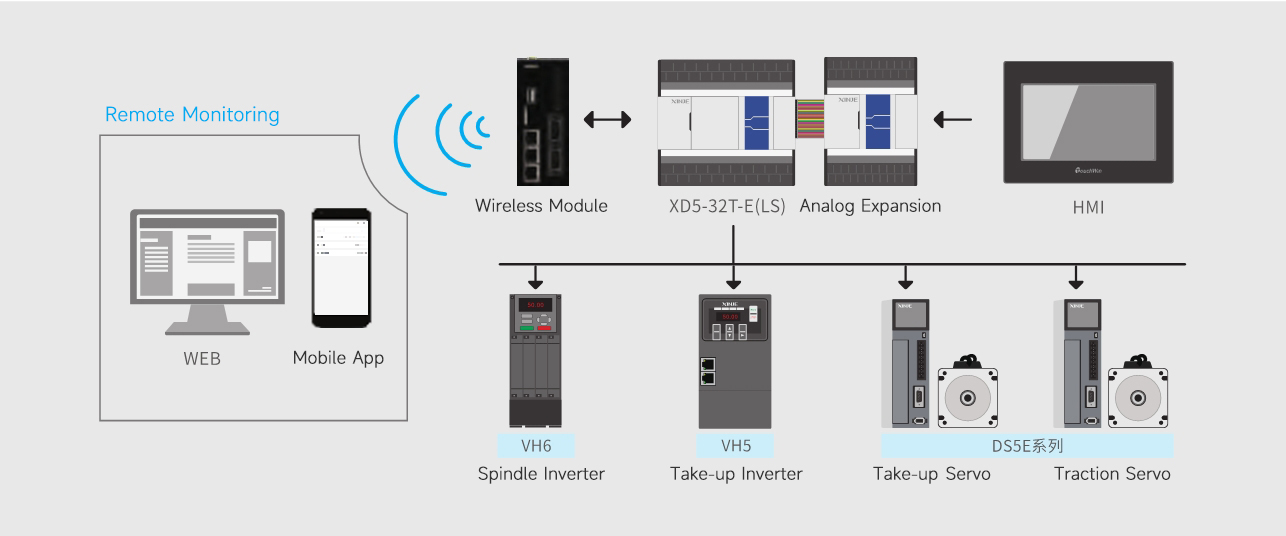

System topology