Wire stripping machine system solution

Wire stripping machine system solution

High wire accuracy, flexible function selection

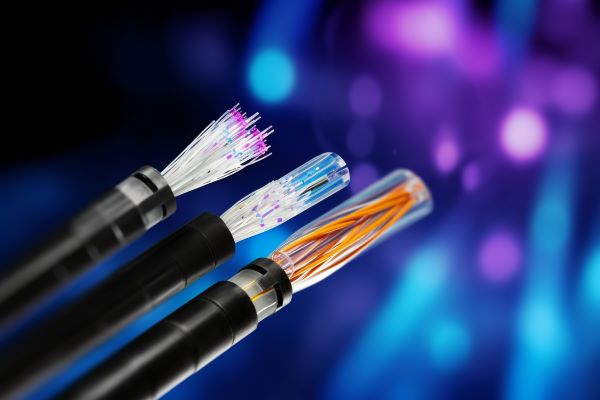

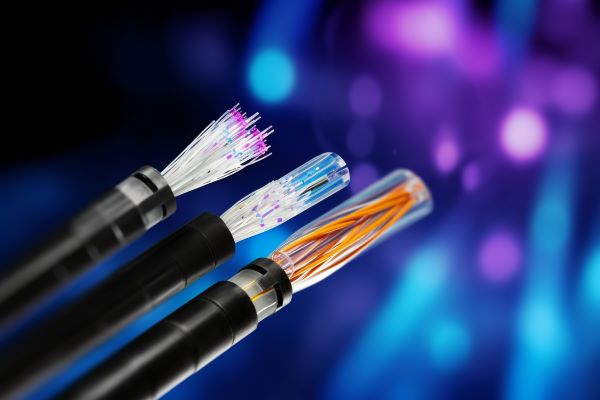

Compared to traditional wire stripping machines, Sunchan wire stripping machines offer more comprehensive functionality to meet various on site application needs. They are commonly used for processing high-voltage lines, multi-layer shielded cables, and are widely applied in fields like electronics, automotive, aerospace, etc.

Industry Background

Wire stripping machines are a type of equipment used in wire harness assembly. With the wire stripping machine as the main component, it can be flexibly equipped with functions such as cutting blades, rotary blades, inkjet coding, wire winding, and material feed loop. Compared to traditional wire stripping machines, Sunchan wire stripping machines offer more comprehensive functionality to meet various on-site application needs. They are commonly used for processing high-voltage and low-voltage wires, multi-layer shielded cables, and are widely applied in fields such as electronics, automotive, aerospace, etc.

Process flow

After the wire passes through the straightening frame for straightening, it is synchronously fed by the front and rear wire feeding wheels to various mechanisms for wire winding, wire stripping, wire cutting, and material feeding. The front and rear wire pressure can be adjusted to ensure that the wire does not slip or get damaged during the feeding process. The inner and outer clamps hold the wire tightly during the wire winding process to prevent wire movement and ensure a smooth cutting edge. The retractable motor can be selected with different blade types for wire cutting and wire stripping respectively.