Wire Harness Terminal Stamping System Solution

Wire Harness Terminal Stamping System Solution

Integrated drive and control design, high repeat positioning accuracy, uniform and precise stamping

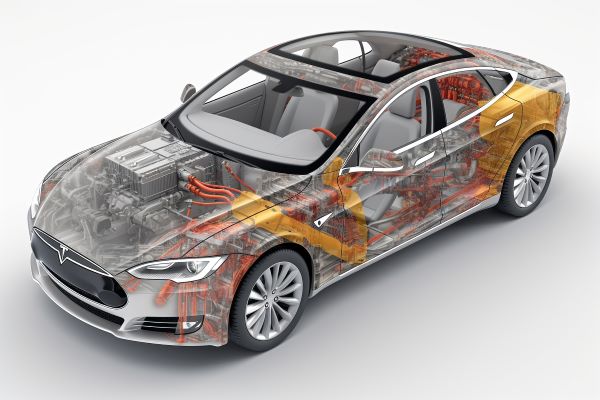

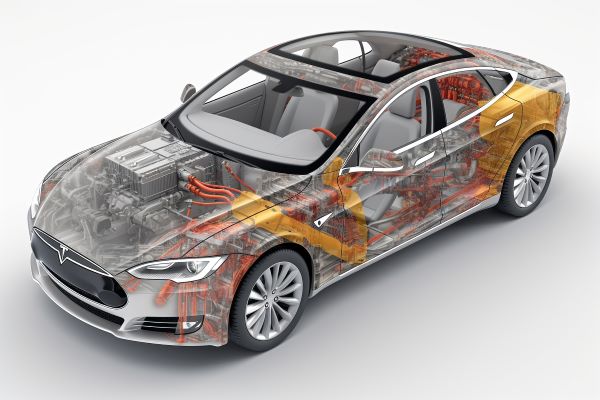

Wire harnesses are key components in automotive circuits that connect various electrical devices, responsible for transmitting communication signals and power between equipment. Terminal crimping is a crucial step in the wire harness manufacturing process.

Industry Background

Wire harnesses are key components in automotive circuits, connecting various electrical devices and transmitting communication signals and power between them. Terminal crimping is a crucial step in the wire harness manufacturing process. Traditional terminal crimping relies on asynchronous motors driving eccentric wheel mechanisms for reciprocating motion to achieve terminal stamping. This method has drawbacks, such as relying entirely on mechanical adjustments for terminal thickness, lacking precise control, and no pressure data feedback during the process, making it difficult to assess terminal quality. These issues can significantly increase quality control costs.

Xinje's wire harness terminal stamping equipment uses a servo control solution, allowing precise control of stamping positions and monitoring terminal forming pressure, which improves the pass rate of terminals and automatically filters out defective products. This enhances production efficiency while significantly reducing management costs.

Control Solution

The wire harness terminal stamping servo machine integrates the process within the servo drive and uses industry-leading procedures. It doesn't require PLC programming, and users can simply call the built-in program to set relevant parameters and begin use immediately.