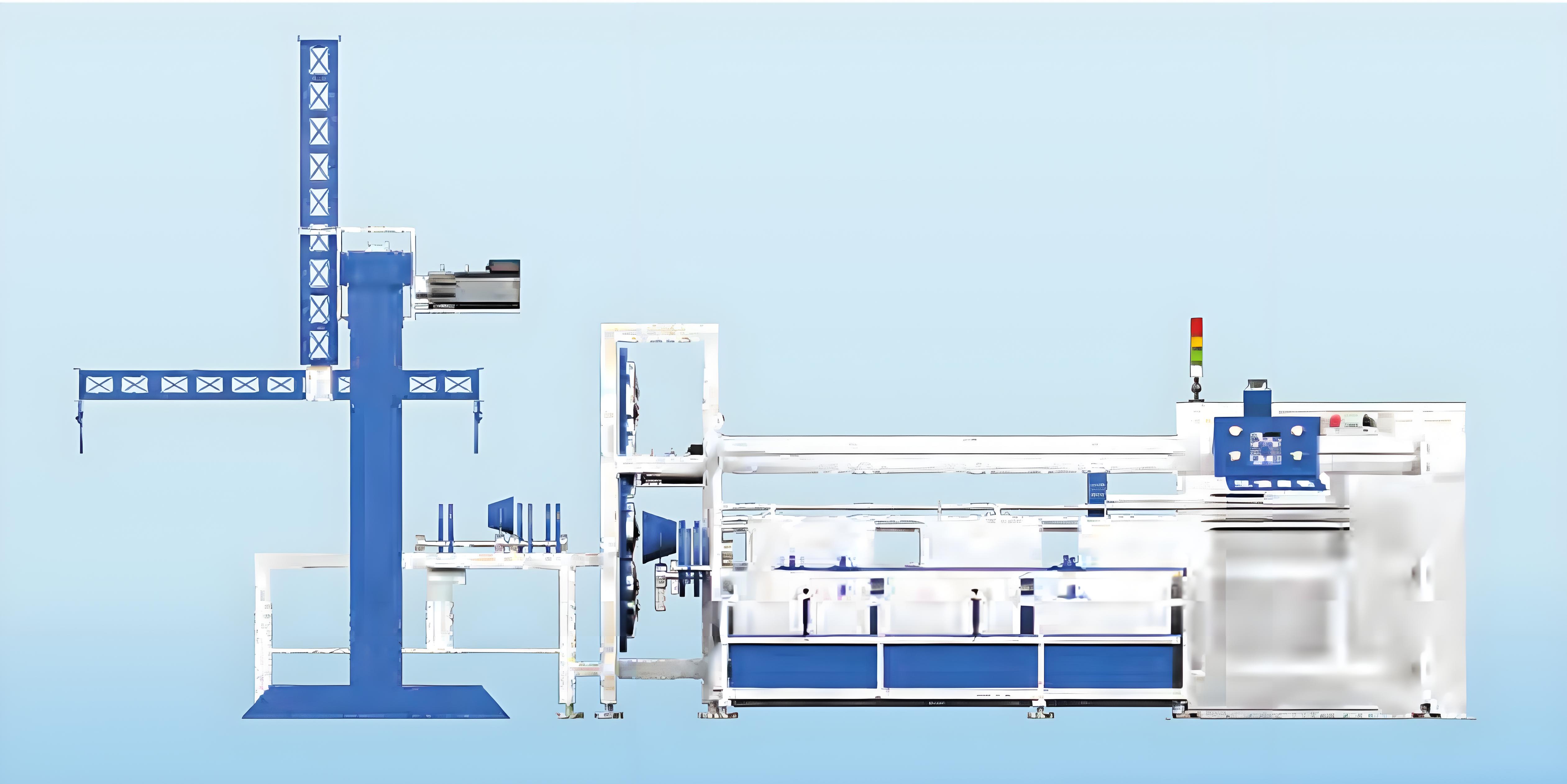

Solution for automatic bamboo breaking machine system

Solution for automatic bamboo breaking machine system

Automatic feeding, high-speed production, quality improvement and efficiency enhancement

The Xinje integrated bamboo production line solution can achieve automatic feeding of bamboo tubes, cutting, breaking and classifying bamboo of various diameters and thicknesses according to strict process requirements, with a breaking speed of up to 9.5 tubes per minute. Solve the problems of high costs, large losses, and safety hazards.

Industry background

China has abundant bamboo resources, and bamboo plants have unique biological, mechanical, and ecological characteristics, as well as good economic, ecological, and social benefits. The existing bamboo processing machinery and equipment in China are very backward and difficult to meet the needs of modern high-quality bamboo product production. The bamboo material preparation and processing process requires multiple single machine equipment, multiple processes, and a large amount of manual cooperation, with low mechanization, high processing costs, high labor intensity, and low processing efficiency. Therefore, it is necessary to overcome the key technology of continuous processing of bamboo segmented and broken, develop key equipment for continuous processing of bamboo segmented and broken, and achieve integrated processing of bamboo. This is of great significance for the development of China's bamboo processing industry and even modern forestry.

The Xinje integrated bamboo production line solution can achieve automatic feeding of bamboo tubes, cutting, breaking and classifying bamboo of various diameters and thicknesses according to strict process requirements, with a breaking speed of up to 9.5 tubes per minute. Solve the problems of high costs, large losses, and safety hazards.

System principle

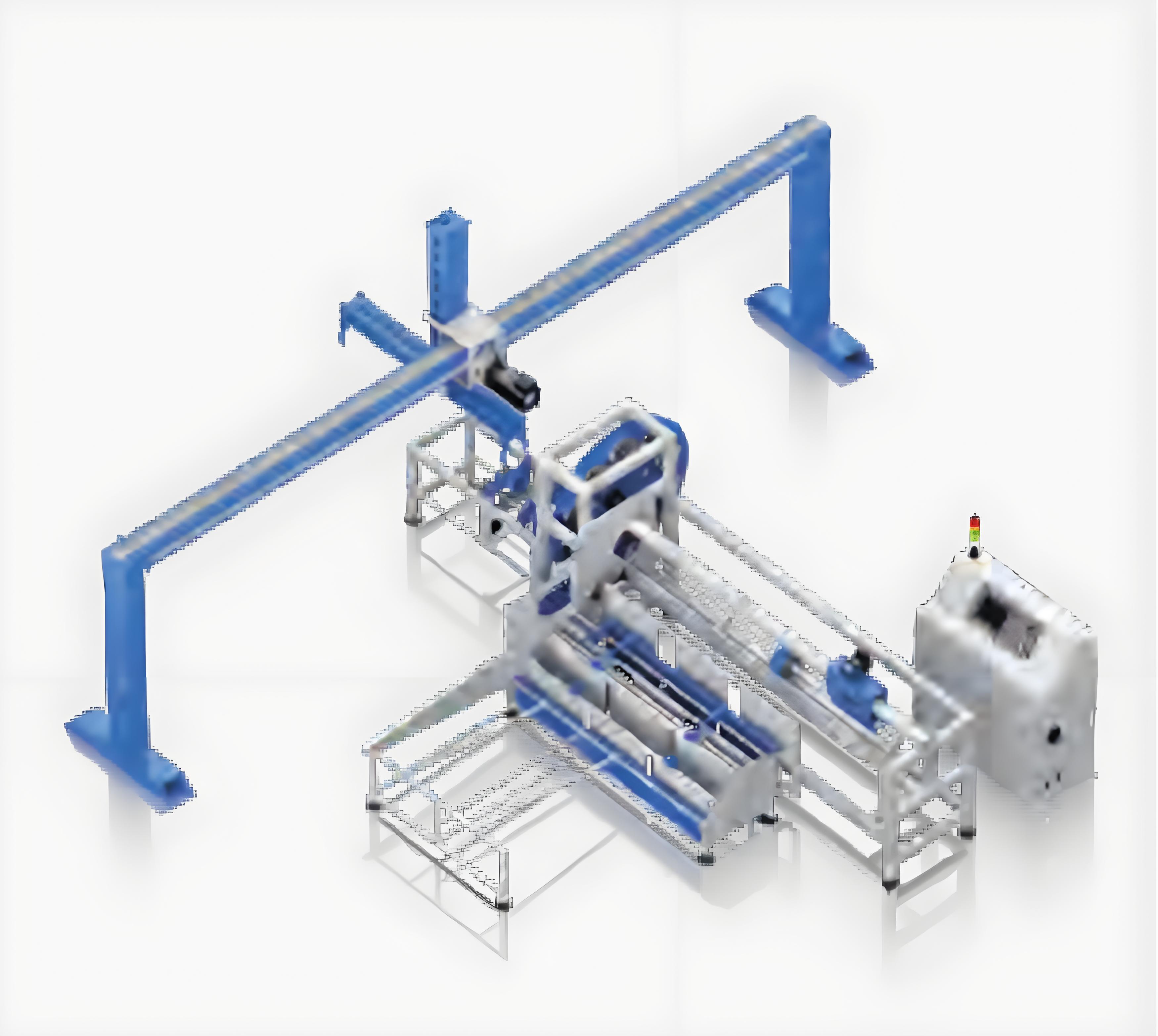

The production process of automatic bamboo breaking machine mainly includes feeding unit, measuring unit, bamboo breaking unit and sorting unit. The production line mainly measures the diameter and inner thickness of bamboo tubes by machine. Then, based on the measurement data, the corresponding bamboo cutting tools are automatically selected for bamboo breaking. The finished products after bamboo breaking are sorted by stacking transition units according to different thicknesses.

Control scheme and system topology

The main functional requirements of the production line include automatic feeding, automatic measurement, automatic tool selection, and automatic classification. "Automatic classification" is one of the highlights of this system. Its characteristics include conveying control for automatic feeding of bamboo tubes, pushing motion control for pushing bamboo, stereo measurement algorithm for measuring bamboo tubes, motion control for switching blade heads, and aircraft mechanical claws for sorting bamboo pieces. XDH-30A16L is selected as the MCU, paired with a six axes servo system to achieve position and synchronization.