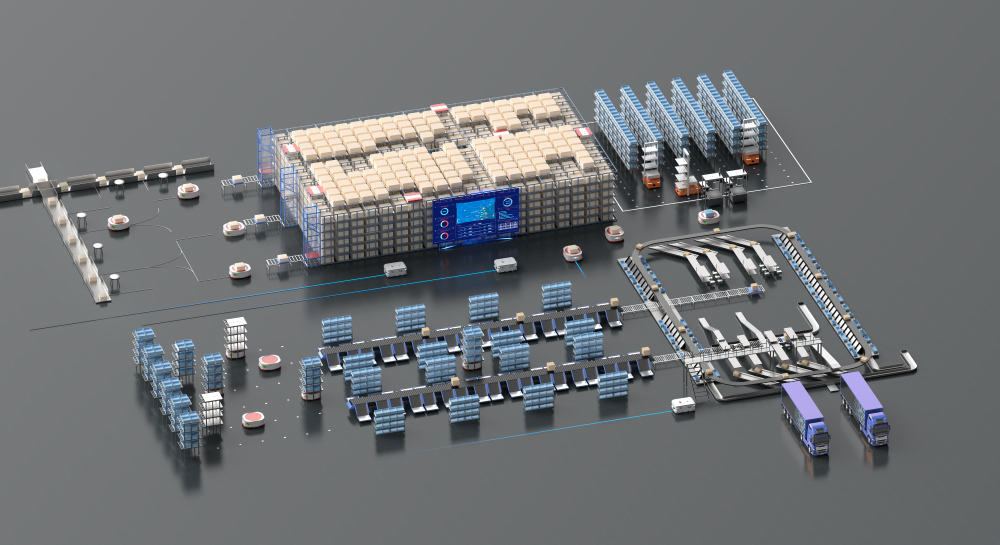

Solution for Automatic Material Handling System

Solution for Automatic Material Handling System

Accurate operation, efficient collaboration, and various scenario applicability

Automatic material handling system refers to an equipment based on advanced technology, used to achieve automated handling and transportation of materials. This system breaks through traditional large-scale conveyor belt equipment, optimizes material handling systems, reduces enterprise material handling costs, and improves the efficiency of material handling systems.

Control solution

The scheme adopts XLQ7 series bus controller, which is combined with EtherCAT bus to complete the walking axis and lifting axis actions (including frequency conversion and servo control scheme), and adapts to various brands of sensors through the controller's built-in Ethernet/IP protocol. Handle track break codes (including 16 segments break codes), call the process function block to make the positions continuous and run without breaks.

Using the data update function of MOVA instruction to achieve real-time speed control in the speed loop. Multi-vehicle operation includes the functions of waiting for the preceding vehicle to work within a safe distance and following the preceding vehicle during operation, forming a rational configuration of material activity index and handling equipment handling index within the system.

System topology

Solution advantages

Speed 300m/min, acceleration 5m/s²

Amhs equipment with a light load of 50-200KG

Speed 260 m/min, Acceleration 2.5 m/s²

Load capacity: 1.5-2 tons for transport

Speed 50-80m/min, Acceleration0.3 m/s²

Load capacity: 3 tons / over 5 tons for transport

Two Drive Options

Adapt to both servo and variable frequency drive forms, using main control PID control to achieve dual closed-loop precise uniform speed and positioning.

Flexible Coordination for Multi-Vehicle Operation

Flexible coordination of multi-vehicle operation in different scenarios, maintaining a safe distance between two vehicles and coordinating with other vehicles.

Multi-Scenario Circular Track

Embedding continuous position control with multiple breaking codes to adapt to circular orbits in more scenarios.

Modular Collaborative Scheduling

The task interaction of modular collaborative vehicle scheduling software ensures real-time communication.

Stable Wireless Signal

Overall coordination with wireless scenarios ensures stable signal strength and low packet loss rate for instruction interaction.