Automated 3D warehouse——Four-way lifting vehicle

Automated 3D warehouse——Four-way lifting vehicle

Efficient and flexible, cost-effective and easy to implement

Xinje is familiar with various fields of warehousing and logistics and their unique requirements, and has developed targeted software and hardware products to provide customers with efficient and future oriented solutions. With a sustainable development mindset and a commitment to technological innovation, we aim to achieve efficient and flexible material systems, reduce costs and expenses, facilitate implementation, and provide comprehensive solutions for customized combinations. Our goal is to provide you with high-quality technological value for your applications.

Industry background

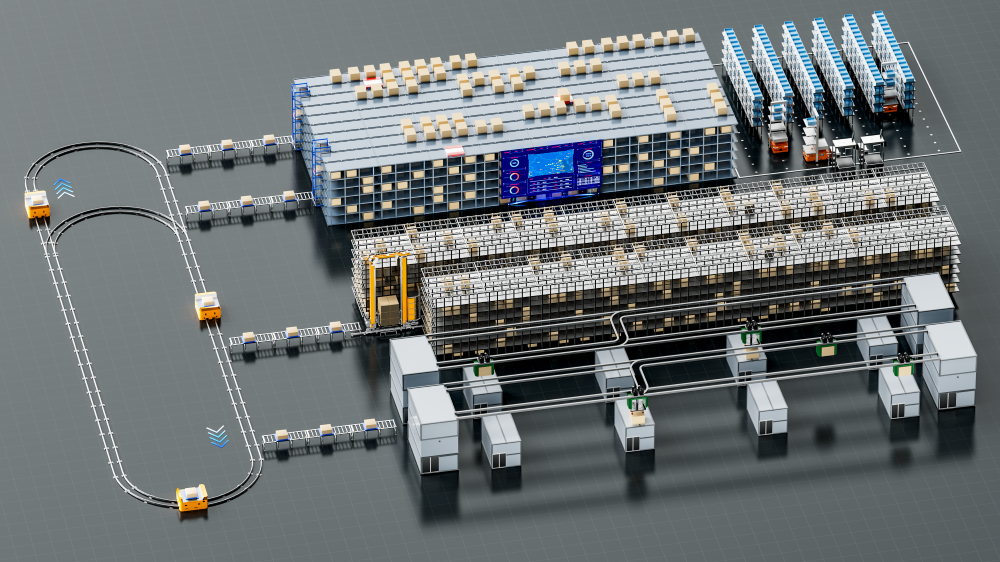

Traditional warehousing faces challenges such as low space utilization, low operational efficiency, and high labor costs. With the development of technology and the demand for enterprise cargo storage, the intensive warehousing industry is constantly pursuing higher operational efficiency, lower costs, and better environmental sustainability. Through technological innovation and development, the intensive warehousing industry is gradually shifting from traditional warehousing models to intelligent, automated, and sustainable forms.

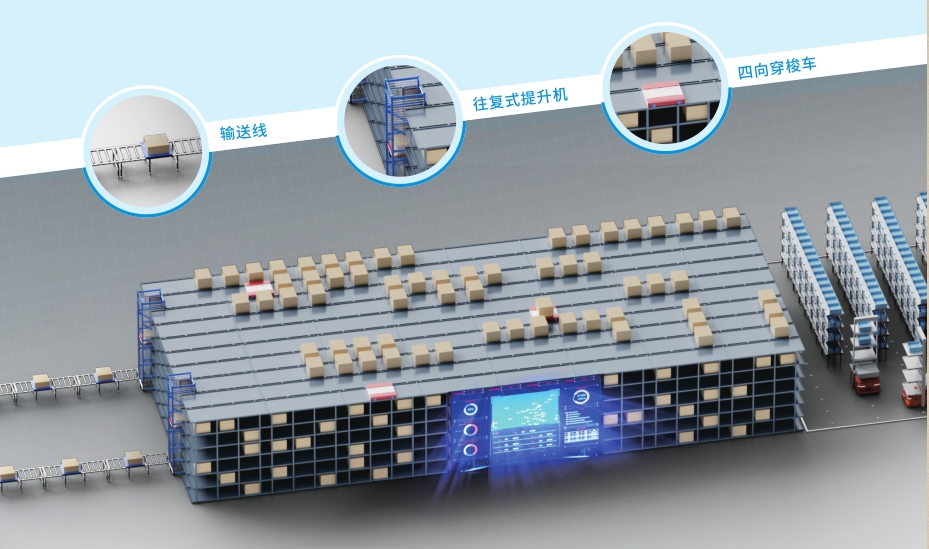

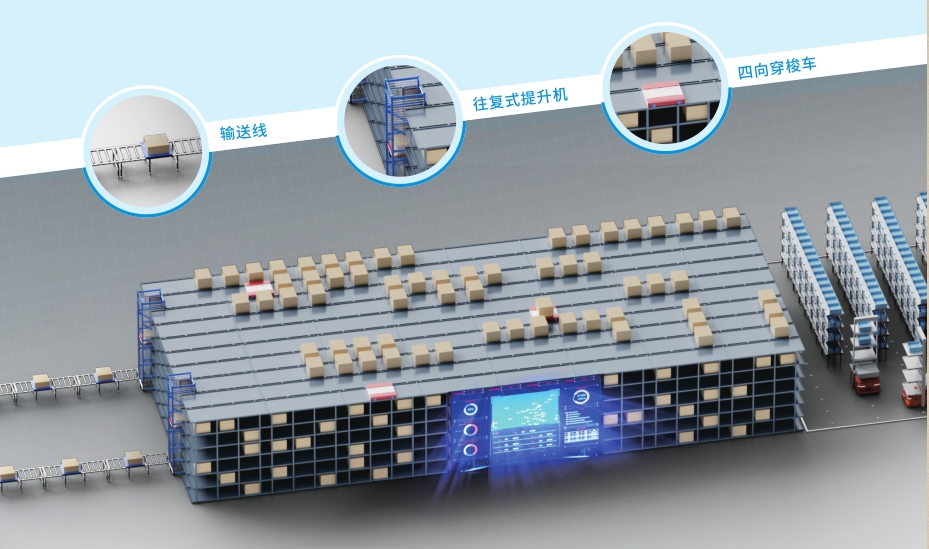

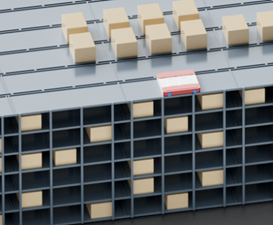

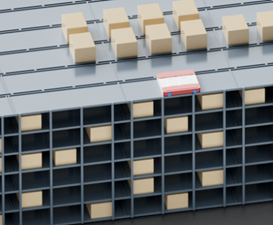

Four-way lifting vehicle

The four-way vehicle realizes the fixed-point warehousing, outbound, and handling actions of goods, and the lifter realizes the docking of goods with the conveyor line, layer changing of goods, and layer changing of small vehicles, breaking down the barriers between layers and stretching the stored two-dimensional space to three-dimensional space, greatly improving storage utilization and achieving dense storage.

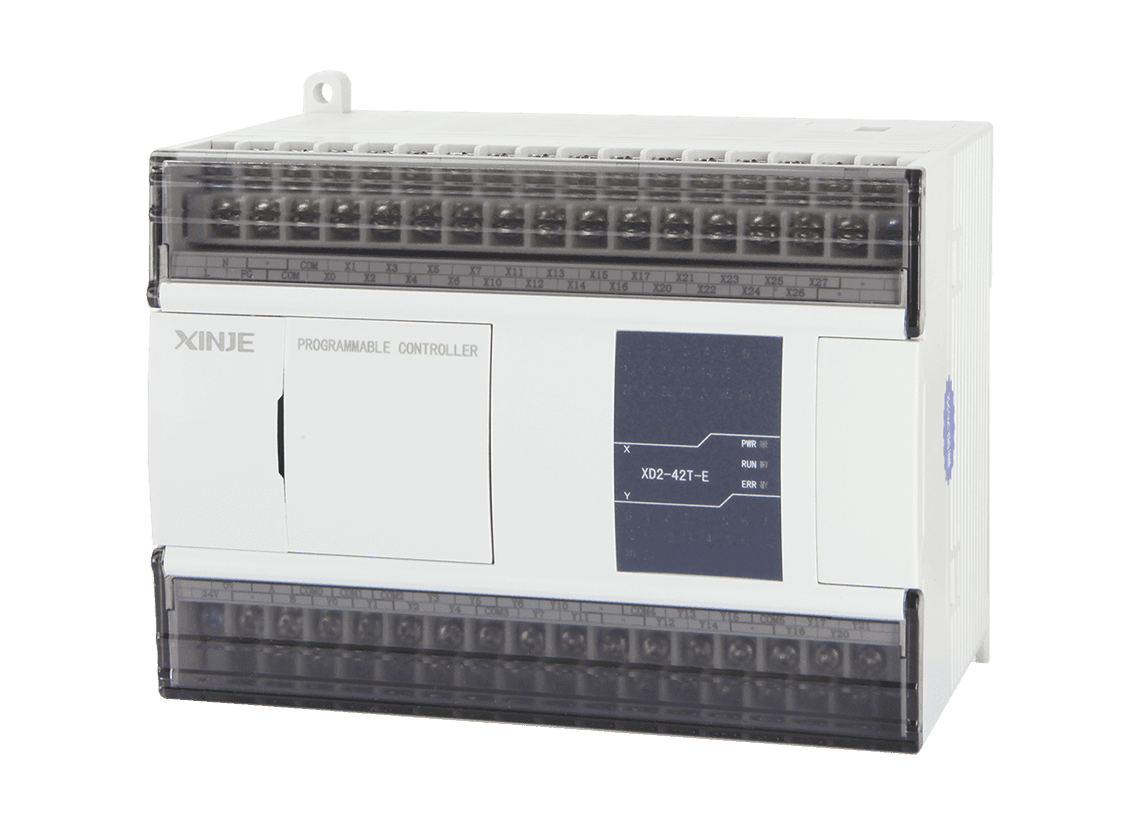

Control solution

The four-way vehicle adopts XL5N series bus motion controller, which uses CANopen bus and low-voltage servo system to achieve motion control. It has high responsiveness, convenient wiring, and strong anti-interference ability. Adopting card type ultra-thin PLC and small size motor to reduce the proportion of internal space. The host comes with multiple types of communication (network port, RS485, RS232, CAN port) integrated with devices such as code readers, distance sensors, battery information, etc., to complete tasks such as warehousing, outbound, and transportation under the scheduling of the warehouse management system.