Solution for label printing machine

Solution for label printing machine

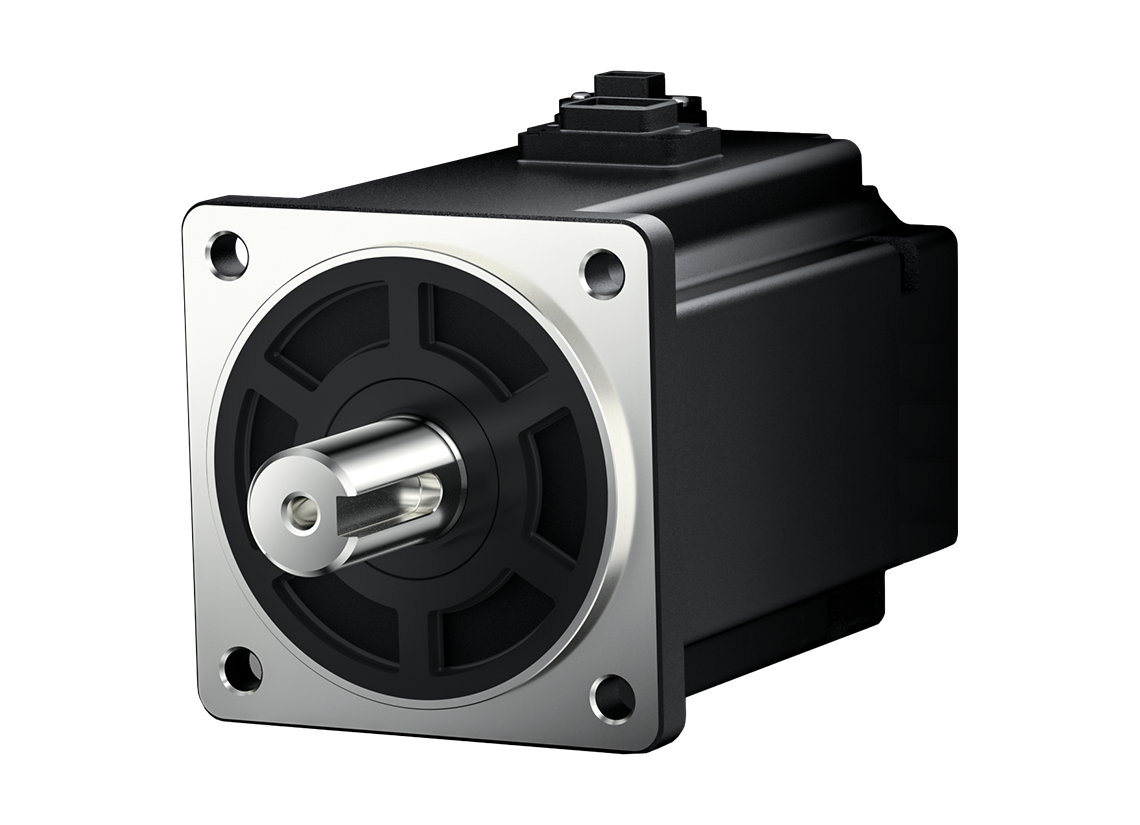

High precision and efficiency, flexible and easy to use, rich modes

Since 2012, the production and demand of China's label printing market have been increasing year by year with the rapid development of downstream industries such as daily chemical products, food, home appliances, and logistics. Faced with the increasing market demand, Xinje provides efficient and reliable automation technology support for the label printing industry, focusing on customers' actual production needs, providing two mature solutions: intermittent printing machines and rotary printing machines, to help the industry's automation transformation and further improve production efficiency.

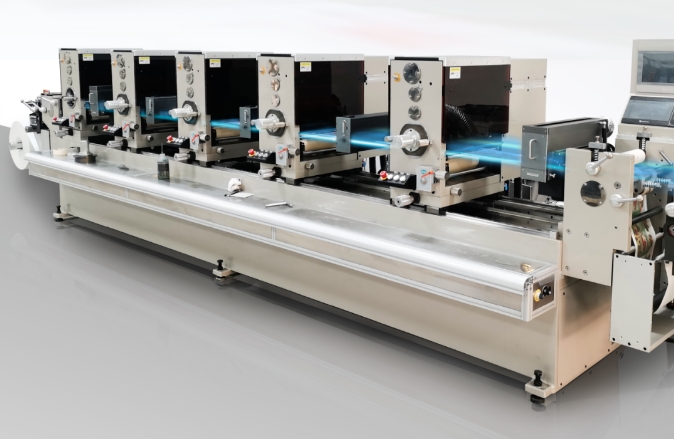

Equipment Introduction

Intermittent printing machines have the characteristics of simple operation, flexible plate changing, and rich functions, suitable for small batch and multi variety production occasions.

The rotary printing machine has flexible plate changing, fast printing speed, high accuracy, and is suitable for large-scale production.

Technological process

Unit type intermittent printing machine

Customers can add color seats according to their needs to meet different production processes. The configuration scheme of 6 cams, 1 flexible, 1 cold wave, and 1 round knife can not only complete the printing process, but also achieve cold wave film covering and finished product die-cutting.

Unit type rotary printing machine

Adopting a configuration scheme of 6 cams, 2 flexible, and 1 round knife to meet the printing needs of customers for different materials. The configuration of the round knife die-cutting seat enables the equipment to achieve printing and die-cutting in one machine.

The printing process adopts the principle of relief printing

The ink supply device of the printing machine first distributes the ink evenly, and then transfers the ink to the printing plate through the ink roller. As the graphic and textual parts on the relief plate are much higher than the non graphic and textual parts on the printing plate, the ink on the ink roller can only be transferred to the graphic and textual parts of the printing plate, while the non graphic and textual parts have no ink. The paper feeding mechanism of the printing machine transports the paper to the printing components of the printing machine. Under the joint action of the printing plate device and the embossing device, the ink in the graphic and textual parts of the printing plate is transferred to the substrate, thus completing the printing of a printed product.

Solution advantages

01. Easy to adjust, reduce costs and increase efficiency

02. High speed, high-precisio

03. Rich in functions and complete in modes

System topology