Bending machine system solution

Bending machine system solution

Automatic compensation, simple operation, and seamless operation

At present, the most important factors for steel processing machinery are the efficiency, accuracy, operational stability, and ability to process complex shapes in graphic processing. The bending hoop machine equipment, which has high work efficiency, high processing accuracy, simple operation, low failure rate, and can automatically complete the straightening, sizing, bending forming, and cutting of steel bars, has comprehensive processing capabilities, can bend in both directions and freely control the expansion and contraction of the core shaft, up and down, and can process more complex shapes, has been widely used in the construction industry.

Industry background

With the development of China's infrastructure industry, the demand for different sizes and shapes of steel bars on various sites is increasing, which has promoted the development of steel bar processing machinery. Currently, the most important factors for steel bar processing machinery are the efficiency, accuracy, operational stability, and ability to process complex shapes. The bending hoop machine equipment, which has high work efficiency, high processing accuracy, simple operation, low failure rate, and can automatically complete the straightening, sizing, bending forming, and cutting of steel bars, has comprehensive processing capabilities, can bend in both directions and freely control the expansion and contraction of the core shaft, up and down, and can process more complex shapes, has been widely used in the construction industry.

Working principle

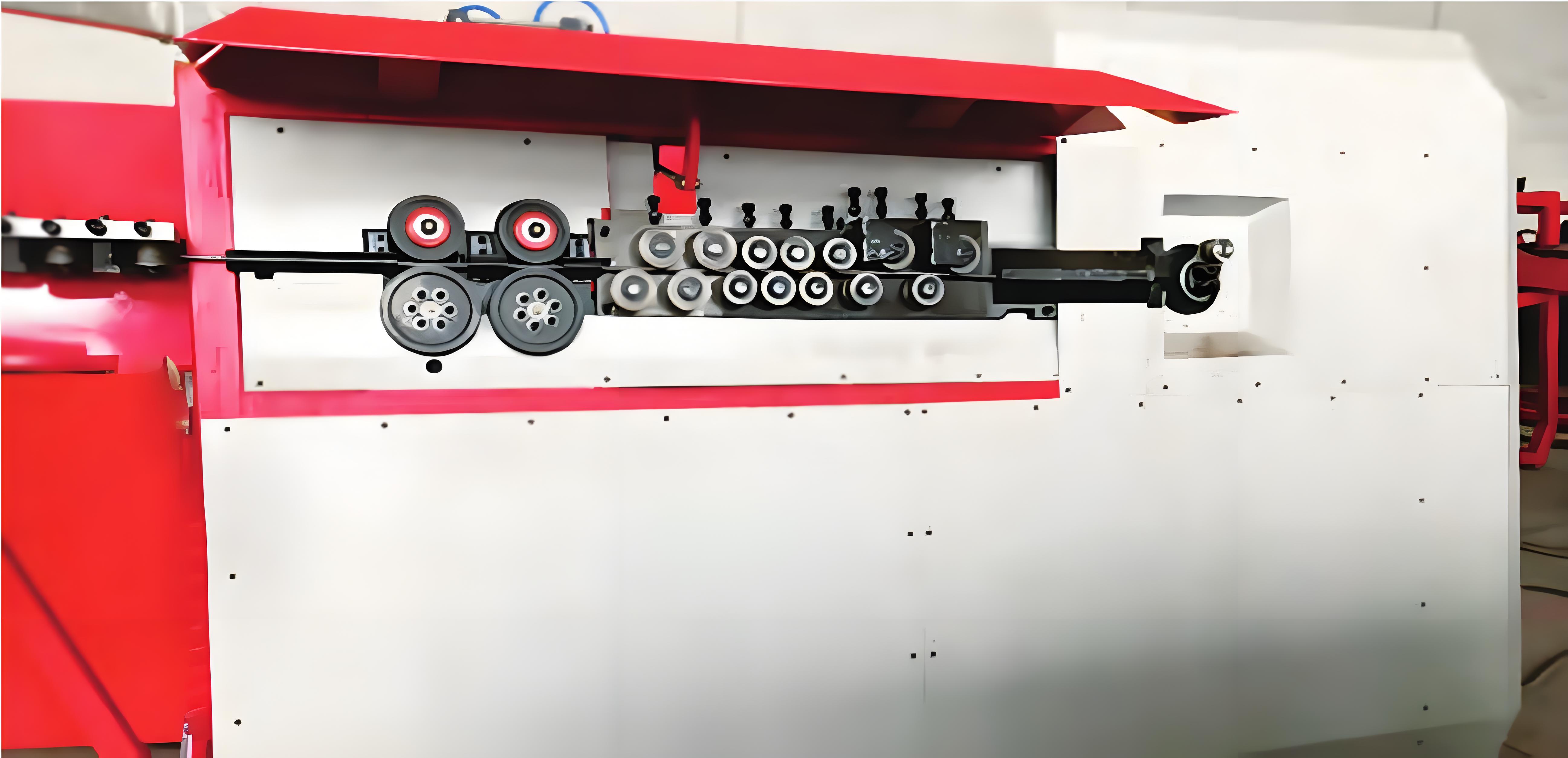

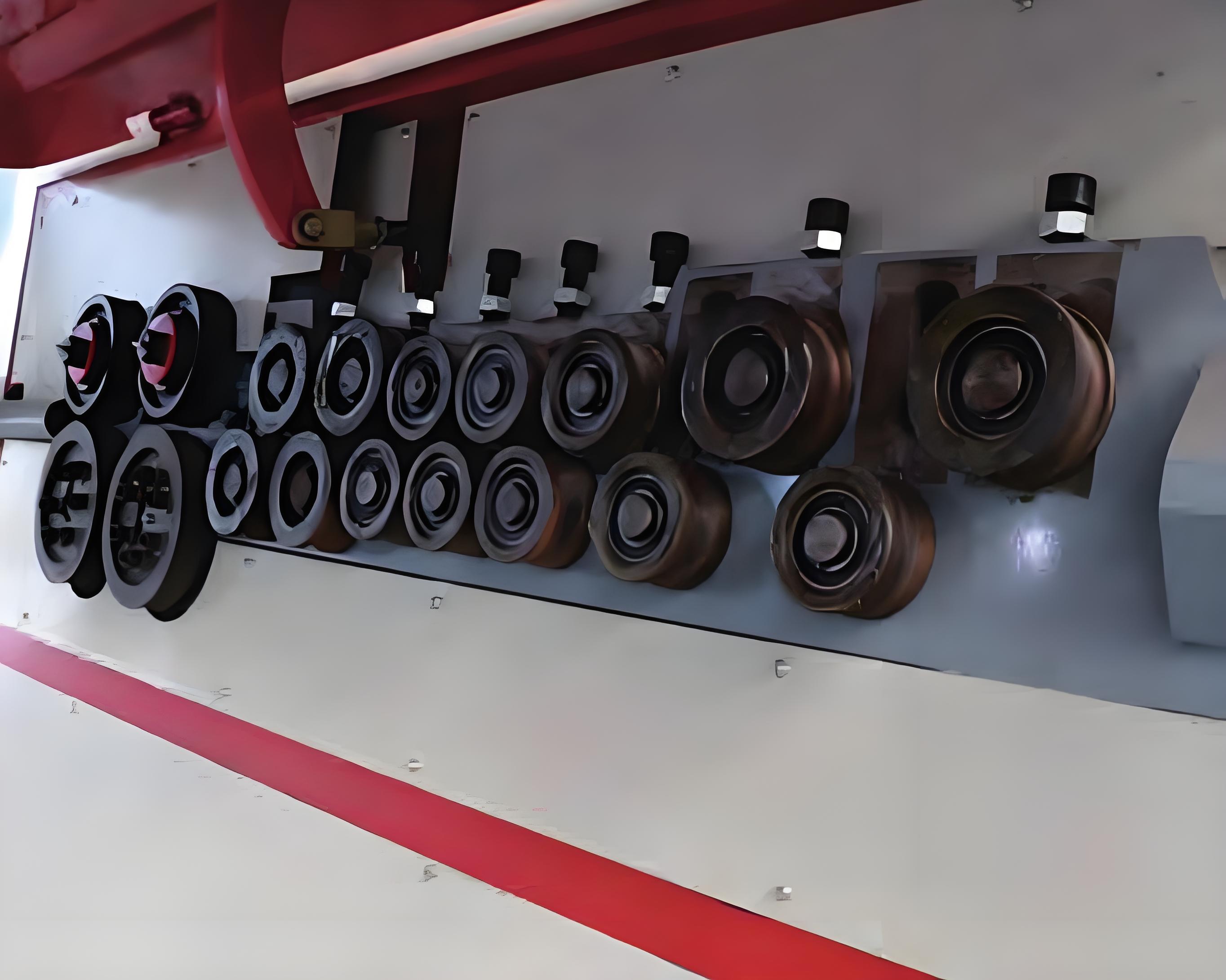

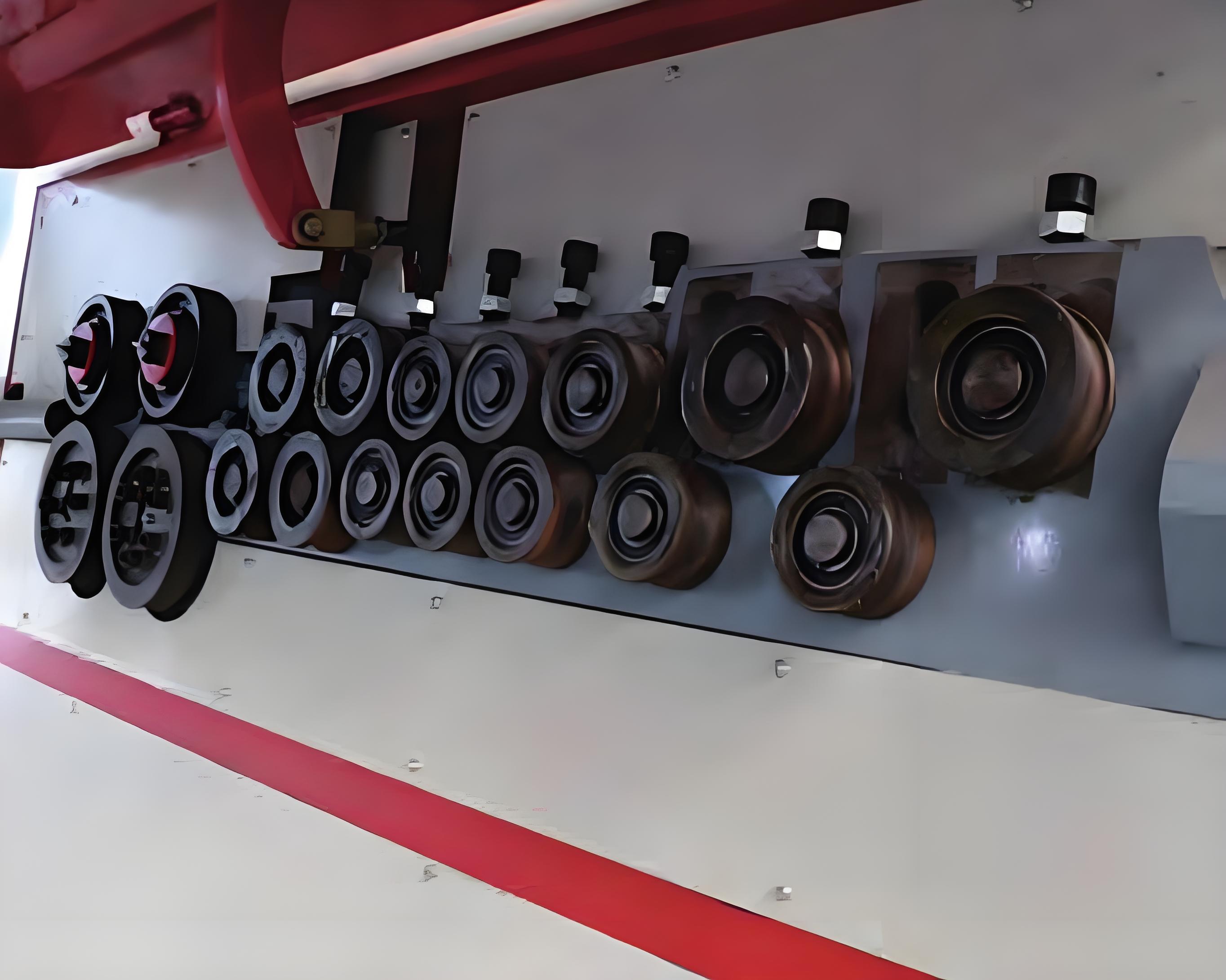

he main body of the bending machine is divided into two parts: the material feeding part and the bending part. By inputting graphic parameters from the customer, the corresponding graphic is displayed on the main interface. After startup, the material feeding and bending action is performed according to the graphic set by the customer. After completing the graphic, cutting and blanking.

It mainly includes three types of shapes: straight bars, positive and negative bending angle shapes, and circles. Feedback positioning is achieved through an external encoder to prevent slipping of steel bars during feeding.

System topology