Solution for automatic framing machine system

Solution for automatic framing machine system

Efficient, easy to debug, and more stable system

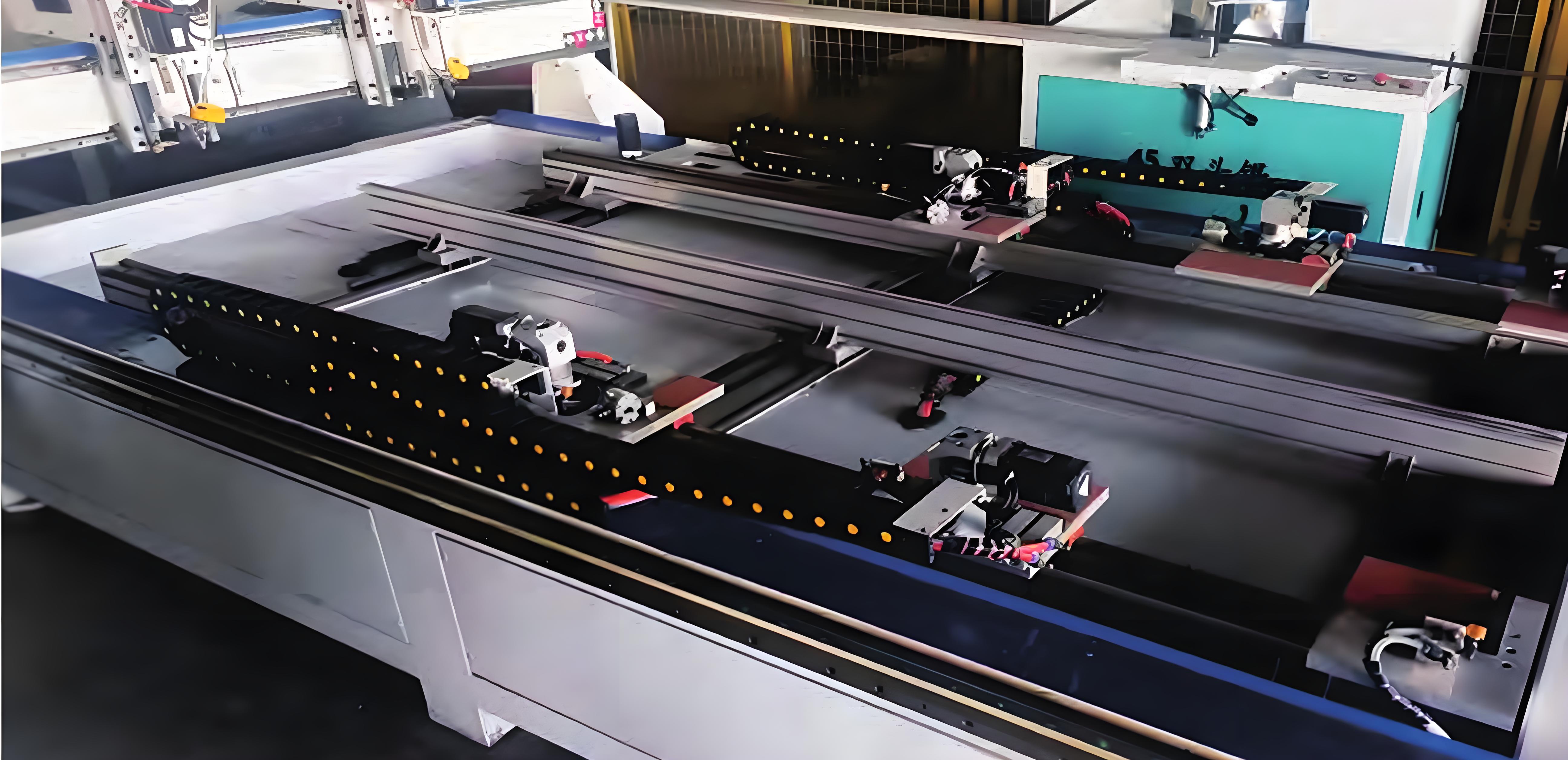

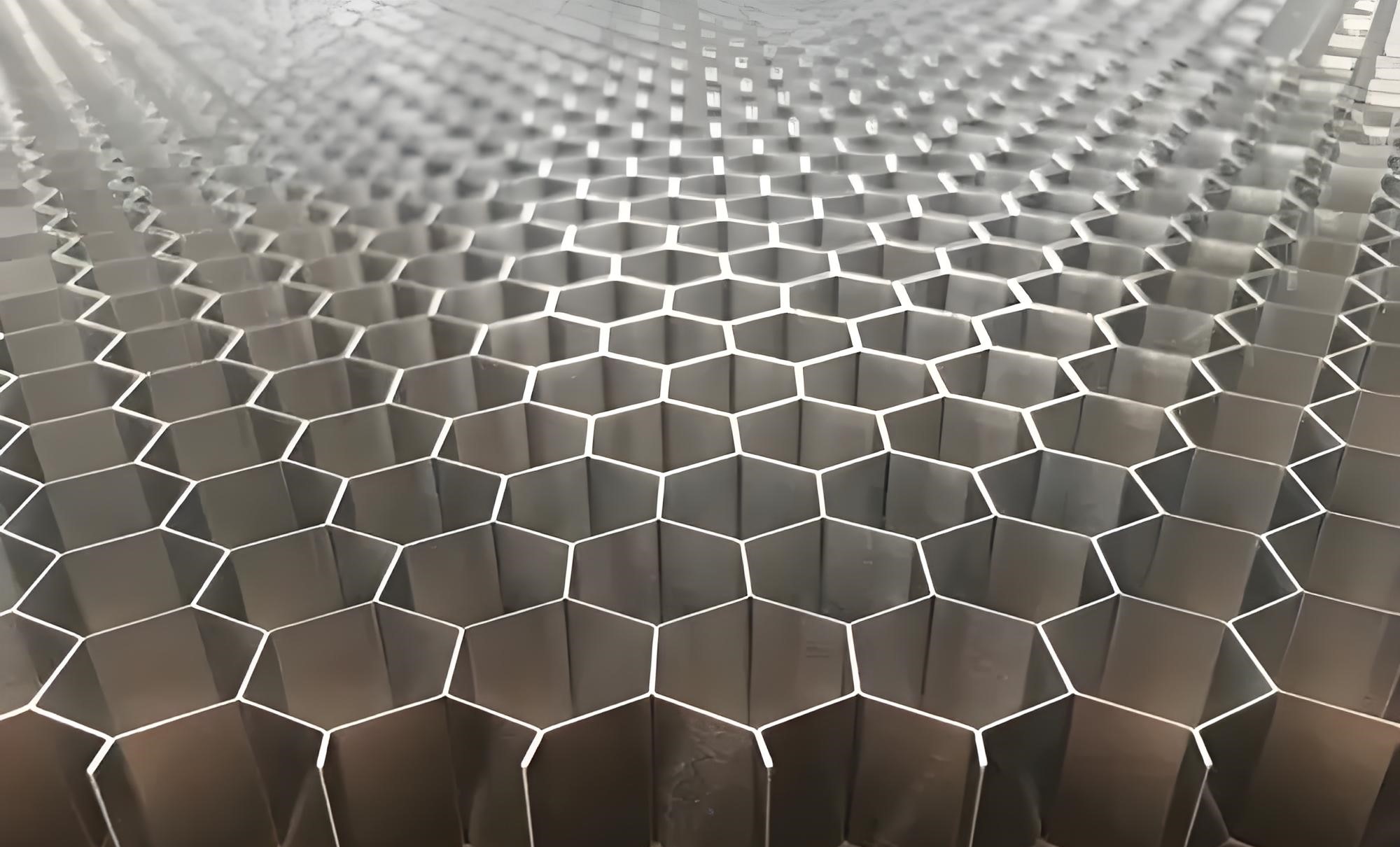

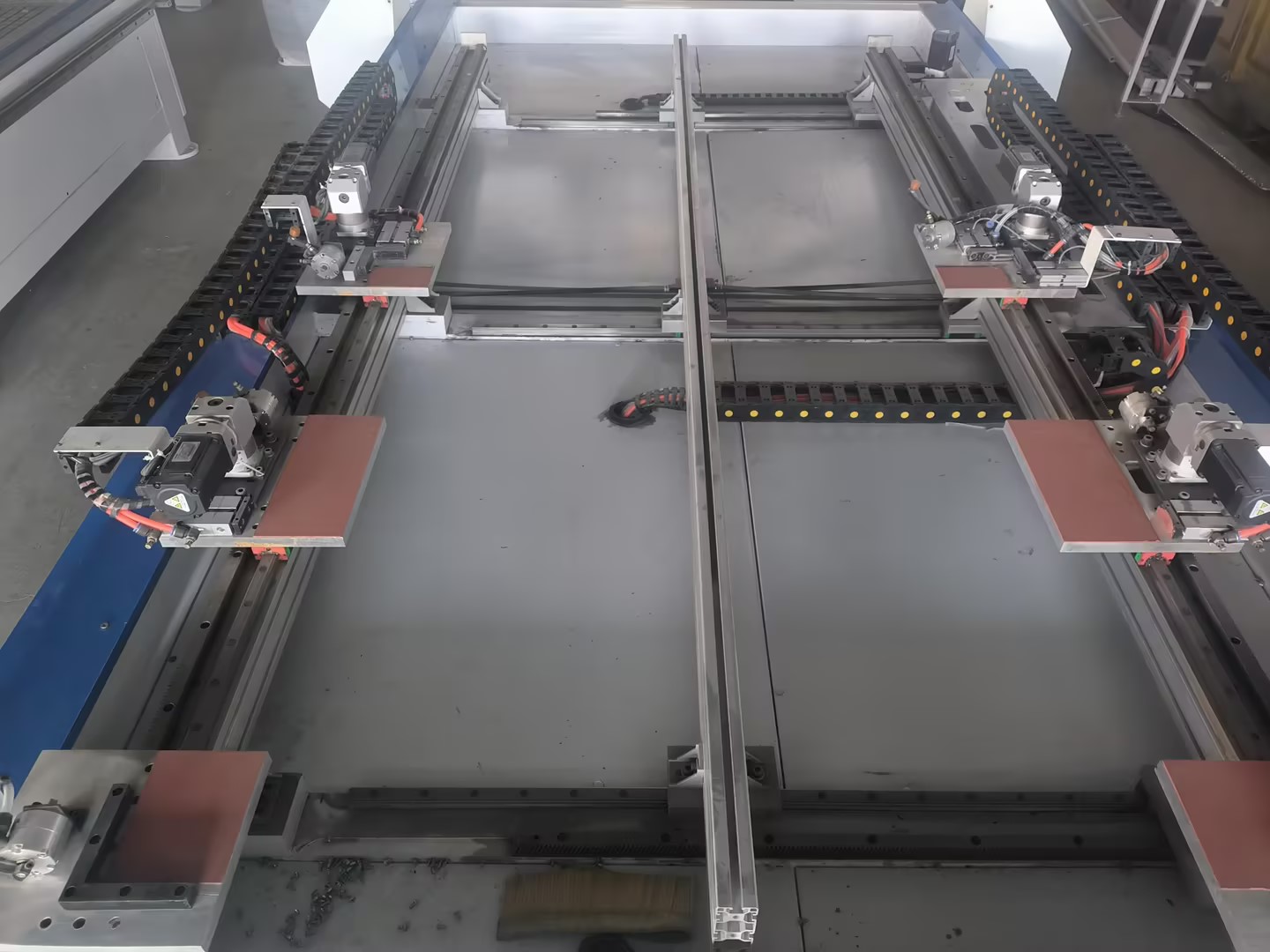

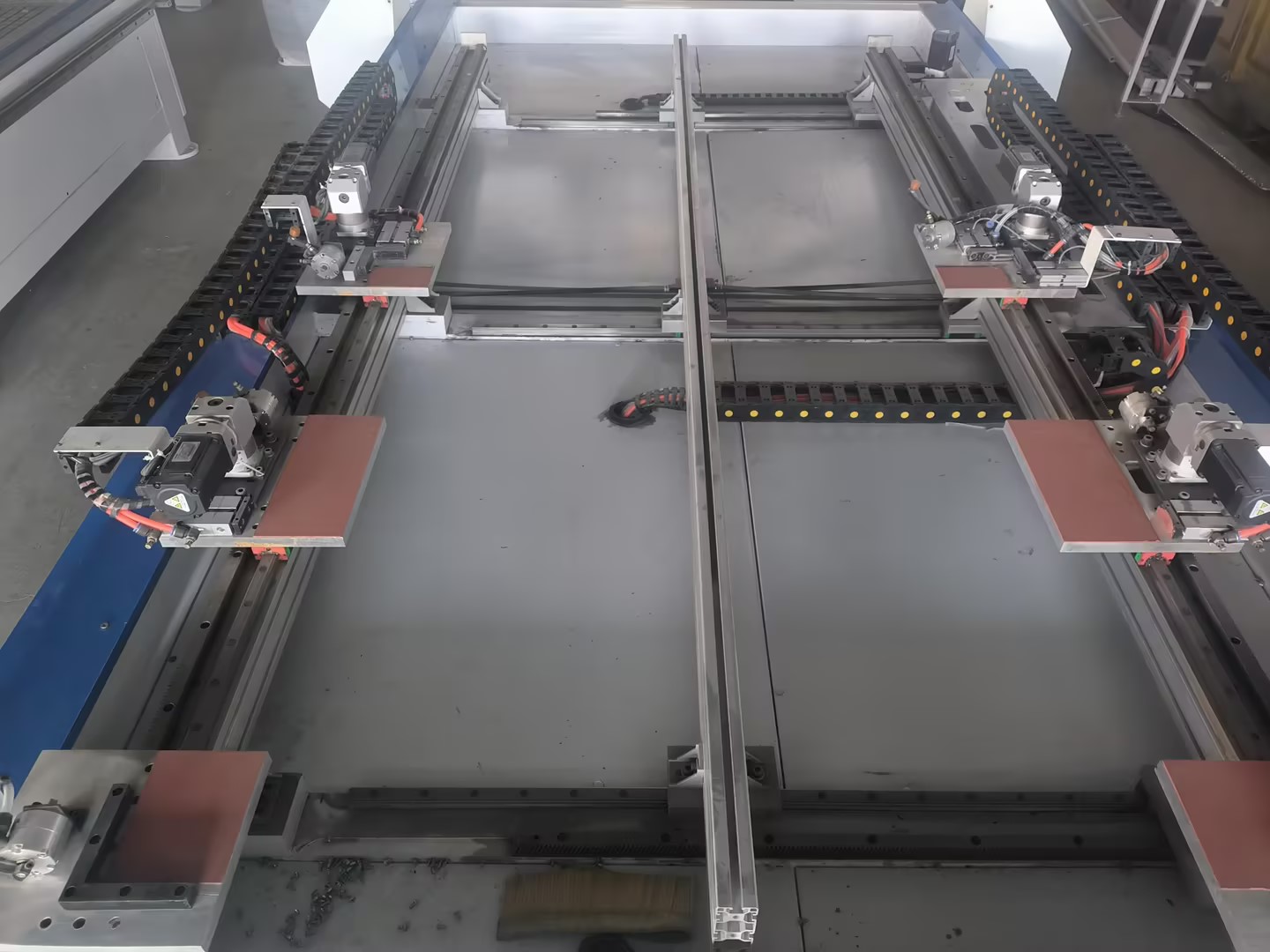

The automatic framing machine is mainly used for framing honeycomb panels, which have a wide range of applications and high market demand. The Xinje servo drive can fully meet the processing technology and precision requirements.

Industry background

Automatic framing has significant advantages over manual framing,

Firstly, the automatic framing machine greatly improves production efficiency, reduces the complexity of manual operations, and incurs significant time costs;

Secondly, the automatic framing machine has higher accuracy, avoiding errors that may occur during manual operation;

The automatic framing machine is easy to operate and can view alarm records to promptly address any issues that may arise during the processing.

The equipment is mainly used for framing honeycomb panels, which have a wide range of applications and high market demand. Xinje servo drives can fully meet the processing technology and precision requirements.

Process principle

Enter relevant parameters such as board length and width in the recipe, adjust the length and width dimensions according to the recipe content in the automatic screen, and automatically calculate the movement position based on the set number of processing screws. According to the requirements of the mechanical and electrical batch, reasonable parameters such as torque and number of turns need to be set. After inserting the board and edging strip, the device automatically screws according to the set parameters such as length, width, position, and speed.

Control solution

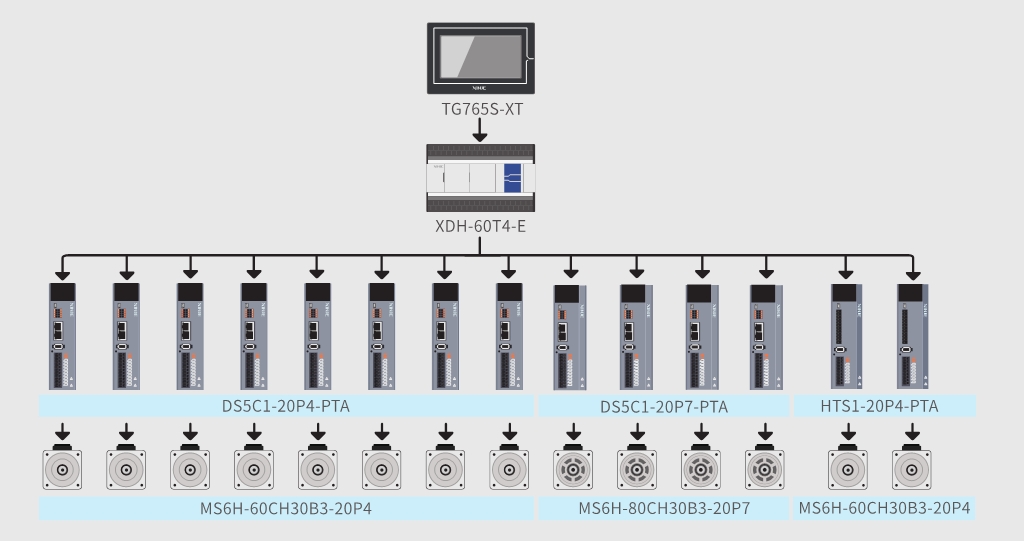

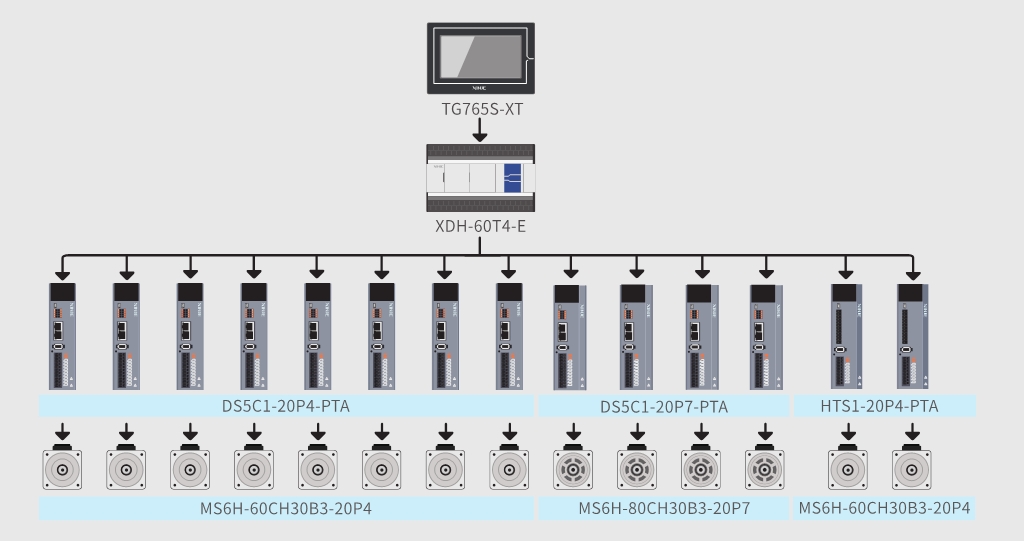

The solution of Xinje automatic framing machine system adopts XDH series PLC and EtherCAT configuration window to simplify programming. The EtherCAT control system does not require hubs and switches, and the wiring is very simple, saving installation costs, reducing the number of engineering designs, drawings, project time for laying cables, and hardware management files. It has the advantages of high efficiency, easy debugging, and stronger system stability.

The scheme adopts DS5C1 series servo drive, supports standard EtherCAT protocol master station, complies with CIA402 standard, supports two-channel high-speed probe function, and the communication cycle of each mode is less than 1ms (32 axes). The standard RJ45 industrial Ethernet fast interface greatly improves wiring efficiency. The power terminals and input/output terminals of the drive are both plug-in terminals, making wiring more convenient and efficient.